Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto Konto ändern

Lieferadresse Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

Notifications

Mark all as read- Passwort ändern

- Mein Profil

- Abmelden

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Mehr bekommen, weniger zahlen mit unseren zeitlich begrenzten angeboten. Jetzt bestellen

Kennametal steht Ihnen zur Diensten

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname:{{SolutionName}}- Produkte

- /

- HARVI™ I TE • Gefast • 4 Schneiden • Weldon®-Schaft • Metrisch

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

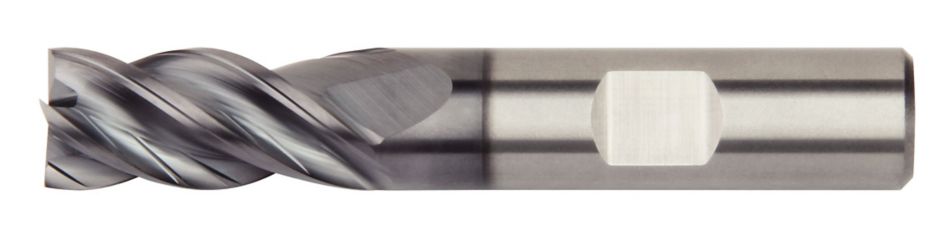

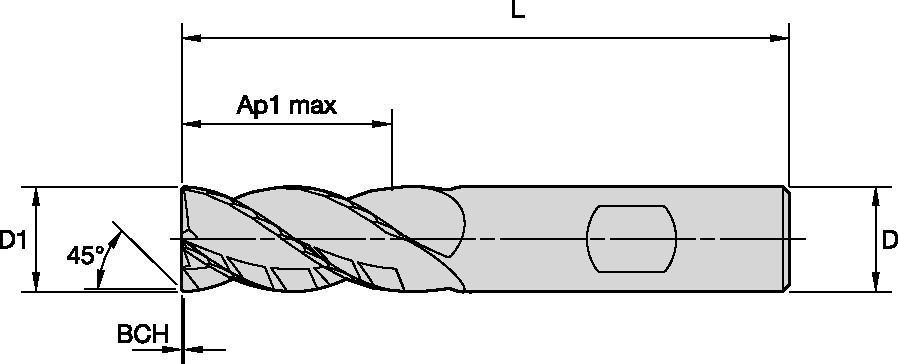

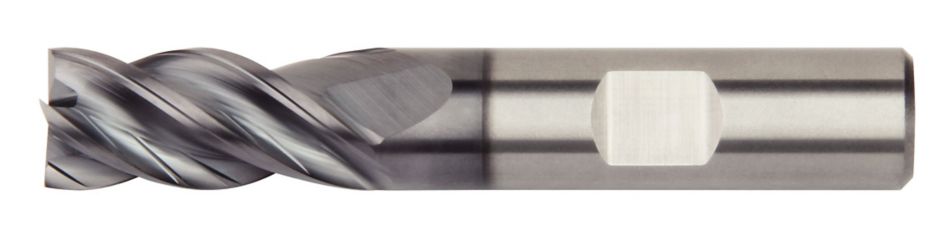

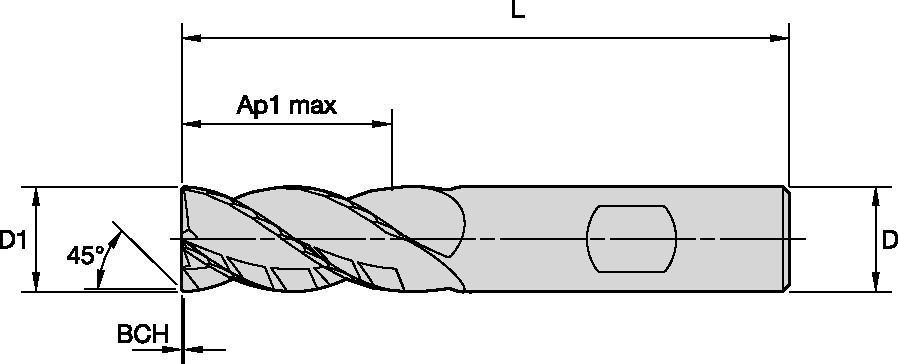

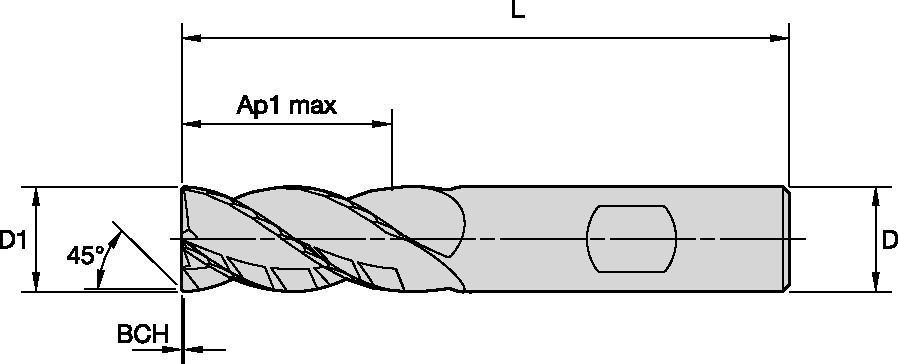

HARVI™ I TE • Gefast • 4 Schneiden • Weldon®-Schaft • Metrisch

HARVI™ I TE Schaftfräser mit vier Spannuten zum Schruppen und Schlichten für die verschiedensten Anwendungen und Werkstoffe

Features and benefits

- Universeller Vollhartmetall-Schaftfräser für Stähle, rostfreien Stahl, Gusseisen und Hochtemperaturlegierungen.

- HARVI™ I TE Vollhartmetall-Schaftfräser decken eine Vielzahl von Bearbeitungen ab, einschließlich dynamischem Fräsen und extremen Rampenbearbeitungen.

- HARVI™ I TE Vollhartmetall-Schaftfräser stehen für maximales Zerspanen, maximale Produktivität und maximalen Nutzen.

- HARVI™ I TE Vollhartmetall-Schaftfräser verfügen über asymmetrische geteilte Spannuten, variable Spirale, verdrehte Stirnfläche, fakturierte exzentrische Entlastung und Spangase innerhalb der Spannuten.

- Zentrales Schneiden für Eintauch- und Rampenarbeiten.

Uses and application

Corner Style: Corner Chamfer

Trochoidal Milling

100147465

Spiralförmiges Interpolieren

Tauchfräsen

Schräg-Eintauchfräsen Ins Volle

Nutenfräsen: Ebene Stirnfläche

Umfangfräsen/Schulterfräsen: Fasen

Werkzeugabmessungen: Schneidreihen: 4

Zylinderschaft – Weldon

Auskammern

Umfangfräsen/Schulterfräsen: Schruppen

Adjustment Factor for Feed and Speed Calculation • Metric

| Ae/D | 2% | 4% | 5% | 8% | 10% | 12% | 20% | 30% | 40% | 50% | 100% | |

| Speed factor | Kv | 2,1 | 1,6 | 1,6 | 1,6 | 1,4 | 1,38 | 1,3 | 1,2 | 1,1 | 1 | 0,9 |

| Feed factor | KFz | 3,58 | 2,56 | 2,3 | 1,84 | 1,67 | 1,54 | 1,25 | 1,09 | 1,02 | 1 | 1 |

| Ae/D | 2% | 4% | 5% | 8% | 10% | 12% | 20% | 30% | 40% | 50% | 100% | |

| Speed factor | Kv | 2.1 | 1.6 | 1.6 | 1.6 | 1.4 | 1.38 | 1.3 | 1.2 | 1.1 | 1 | 0.9 |

| Feed factor | KFz | 3.58 | 2.56 | 2.3 | 1.84 | 1.67 | 1.54 | 1.25 | 1.09 | 1.02 | 1 | 1 |

HARVI™ I TE • 4 Spannuten • Anwendungsdaten • Metrisch

| Ae/D | 2.00% | 4.00% | 5.00% | 8.00% | 10.00% | 20.00% | 30.00% | 40.00% | 50.00% | |

| Speed factor | Kv | 2 | 1.5 | 1.45 | 1.4 | 1.35 | 1.25 | 1.2 | 1 | 1 |

| Feed factor | KFz | 2.4 | 2.3 | 2.2 | 2 | 1.7 | 1.25 | 1.02 | 1 | 1 |

|  |  | |||||||||||||||||||||

| Side Milling (A) and Slotting (B) | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||||||||||||

| KCPM15/KCSM15 | D1 | ||||||||||||||||||||||

| A | B | Cutting Speed | |||||||||||||||||||||

| Material | ap | ae | ap | Min | Max | mm | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 5,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | 18,0 | 20,0 | 25,0 | ||

| P | 0 | 1,5 x D | 0,5 x D | 1,25 x D | 150 | – | 200 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 1 | 1,5 x D | 0,5 x D | 1,25 x D | 150 | – | 200 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 2 | 1,5 x D | 0,5 x D | 1,25 x D | 140 | – | 190 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 | |

| 3 | 1,5 x D | 0,5 x D | 1,25 x D | 120 | – | 160 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 4 | 1,5 x D | 0,5 x D | 1,25 x D | 90 | – | 150 | fz | 0,008 | 0,010 | 0,012 | 0,021 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 | |

| 5 | 1,5 x D | 0,5 x D | 1,25 x D | 60 | – | 100 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 6 | 1,5 x D | 0,5 x D | 1,25 x D | 50 | – | 75 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| M | 1 | 1,5 x D | 0,5 x D | 1,25 x D | 90 | – | 115 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,5 x D | 0,5 x D | 1,25 x D | 60 | – | 80 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,5 x D | 0,5 x D | 1,00 x D | 60 | – | 70 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |

| K | 1 | 1,5 x D | 0,5 x D | 1,00 x D | 120 | – | 150 | fz | 0,011 | 0,013 | 0,016 | 0,027 | 0,031 | 0,040 | 0,048 | 0,066 | 0,079 | 0,091 | 0,102 | 0,111 | 0,119 | 0,125 | 0,136 |

| 2 | 1,5 x D | 0,5 x D | 1,00 x D | 110 | – | 140 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 | |

| 3 | 1,5 x D | 0,5 x D | 1,00 x D | 110 | – | 130 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| S | 1 | 1,5 x D | 0,3 x D | 0,75 x D | 50 | – | 90 | fz | 0,009 | 0,011 | 0,013 | 0,022 | 0,026 | 0,033 | 0,040 | 0,055 | 0,067 | 0,077 | 0,087 | 0,096 | 0,104 | 0,111 | 0,125 |

| 2 | 1,5 x D | 0,3 x D | 0,75 x D | 50 | – | 80 | fz | 0,007 | 0,009 | 0,011 | 0,018 | 0,021 | 0,027 | 0,032 | 0,044 | 0,053 | 0,062 | 0,070 | 0,077 | 0,083 | 0,089 | 0,100 | |

| 3 | 1,5 x D | 0,5 x D | 0,50 x D | 25 | – | 40 | fz | 0,005 | 0,006 | 0,007 | 0,012 | 0,014 | 0,018 | 0,021 | 0,029 | 0,035 | 0,041 | 0,046 | 0,051 | 0,055 | 0,059 | 0,067 | |

| 4 | 1,5 x D | 0,5 x D | 1,25 x D | 50 | – | 60 | fz | 0,006 | 0,007 | 0,009 | 0,015 | 0,017 | 0,023 | 0,028 | 0,040 | 0,049 | 0,057 | 0,064 | 0,071 | 0,076 | 0,082 | 0,092 | |

| H | 1 | 1,5 x D | 0,5 x D | 1,00 x D | 80 | – | 140 | fz | 0,008 | 0,010 | 0,012 | 0,021 | 0,024 | 0,030 | 0,036 | 0,049 | 0,059 | 0,069 | 0,077 | 0,084 | 0,091 | 0,097 | 0,107 |

| 2 | 1,5 x D | 0,2 x D | 1,00 x D | 70 | – | 120 | fz | 0,006 | 0,008 | 0,009 | 0,016 | 0,018 | 0,022 | 0,027 | 0,037 | 0,044 | 0,051 | 0,057 | 0,063 | 0,067 | 0,071 | 0,078 | |