Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto

Konto ändern

Lieferadresse

Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

-

Notifications

Mark all as read - Passwort ändern

- Mein Profil

- Abmelden

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Beginnen Sie das Jahr 2024 mit phänomenalen Einsparungen bei Bohrwerkzeugen.

Jetzt bestellen.

Kennametal steht Ihnen zur Diensten

Artikel

erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname: {{SolutionName}}- Produkte

- /

- Pilotbohrer • B505Z • K10 • A-Schaft • NC-Anbohrer ohne innere Kühlmittelzuführung

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

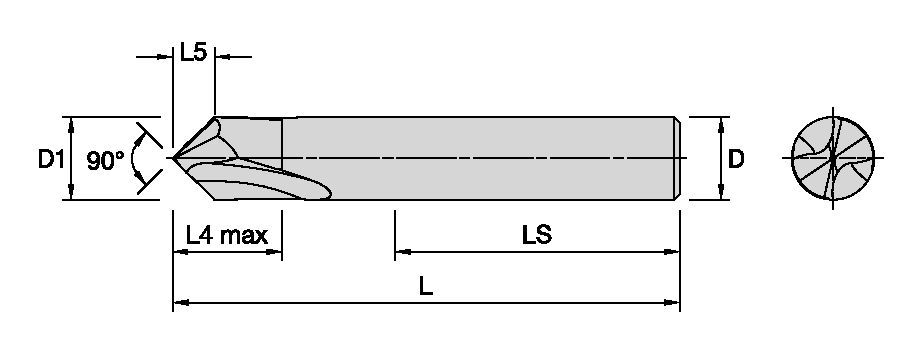

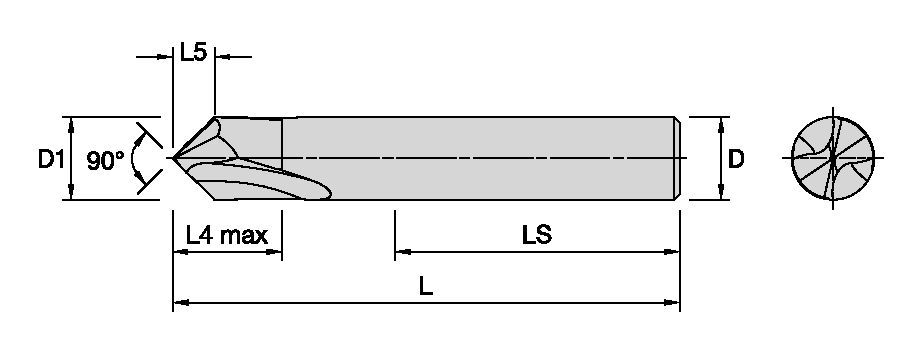

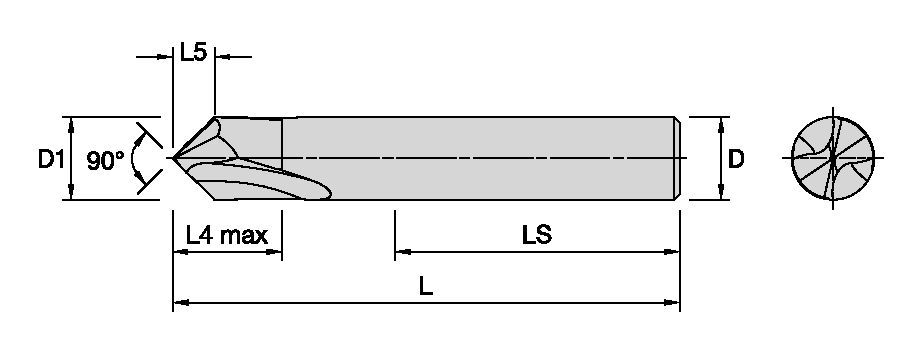

Pilotbohrer • B505Z • K10 • A-Schaft • NC-Anbohrer ohne innere Kühlmittelzuführung

NC-Anbohrer • Keine innere Kühlmittelzuführung

Features and benefits

- NC-Anbohrer ohne innere Kühlmittelzuführung.

- Anwendungsspezifischer Vollhartmetall-Bohrer für das Anbohren vor dem kompletten Bohrzyklus, der für eine bessere Positionierung der Bohrung sorgt.

- Mit kurzer Spannutlänge, ohne Fase oder Körperentlastung, ist er ausschließlich für das Anbohren konzipiert.

- 90° zum Anbohren für HSS-Bohrer.

Uses and application

Bohren: Konvexe Eintrittsfläche

| Tolerance • Metric | ||

| D1 | tolerance h8 + / - | tolerance h6 + / - |

|

|

0,000/-0,018 | 0,000/-0,008 |

|

|

0,000/-0,022 | 0,000/-0,009 |

|

|

0,000/-0,027 | 0,000/-0,011 |

| Tolerance • Inch | ||

| D1 | tolerance h8 + / - | tolerance h6 + / - |

|

|

.0000/-.0007 | .0000/-.0003 |

|

|

.0000/-.0009 | .0000/-.0004 |

|

|

.0000/-.0011 | .0000/-.0004 |

NC-Anbohrer • B50_ • Sorte K10 • Trockenbearbeitung und Außenkühlung • Bohrerdurchmesser 3–20 mm • Metrisch

| Material

|

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||

| Cutting Speed

|

Metric | ||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| P | 0 | 50 | 65 | 100 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 |

| 1 | 40 | 55 | 80 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 2 | 40 | 55 | 80 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 3 | 40 | 55 | 80 | mm/r | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 4 | 40 | 55 | 80 | mm/r | 0,05–0,08 | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,22 | 0,16–0,24 | |

| 5 | 30 | 40 | 60 | mm/r | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| 6 | 30 | 40 | 60 | mm/r | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| M | 1 | 30 | 35 | 50 | mm/r | 0,04–0,07 | 0,05–0,09 | 0,06–0,11 | 0,80–0,13 | 0,09–0,15 | 0,10–0,17 | 0,11–0,20 | 0,12–0,23 |

| 2 | 30 | 40 | 50 | mm/r | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| 3 | 25 | 30 | 40 | mm/r | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| K | 1 | 60 | 90 | 120 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 |

| 2 | 60 | 80 | 100 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| 3 | 60 | 90 | 120 | mm/r | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| N | 1 | 90 | 230 | 270 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 |

| 2 | 90 | 220 | 270 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 3 | 90 | 180 | 225 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 4 | 90 | 130 | 270 | mm/r | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| S | 1 | 20 | 25 | 30 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 |

| 2 | 10 | 20 | 30 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 3 | 20 | 25 | 40 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 4 | 20 | 25 | 50 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| Material

|

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

|||||||||||

| Material

|

Cutting Speed

|

Inch | |||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| P | 0 | 160 | 210 | 330 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 |

| 1 | 130 | 180 | 260 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 | |

| 2 | 130 | 180 | 260 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 | |

| 3 | 130 | 180 | 260 | IPR | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.011 | |

| 4 | 130 | 180 | 260 | IPR | .002–.003 | .002–.004 | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.009 | .006–.009 | |

| 5 | 100 | 130 | 200 | IPR | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .005–.007 | .006–.008 | |

| 6 | 100 | 130 | 200 | IPR | .001–.002 | .001–.002 | .002–.003 | .002–.004 | .003–.005 | .004–.006 | .005–.007 | .006–.008 | |

| M | 1 | 100 | 110 | 160 | IPR | .002–.003 | .002–.004 | .002–.004 | .032–.005 | .004–.006 | .004–.007 | .004–.008 | .005–.009 |

| 2 | 100 | 130 | 160 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.006 | .004–.007 | .004–.008 | |

| 3 | 80 | 100 | 130 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.005 | .003–.006 | .004–.007 | .004–.008 | |

| K | 1 | 200 | 300 | 390 | IPR | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.010 | .008–.012 |

| 2 | 200 | 260 | 330 | IPR | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.010 | .008–.012 | |

| 3 | 200 | 300 | 390 | IPR | .002–.005 | .003–.006 | .004–.006 | .005–.007 | .006–.008 | .006–.009 | .007–.010 | .008–.012 | |

| N | 1 | 300 | 750 | 890 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 |

| 2 | 300 | 720 | 890 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 | |

| 3 | 300 | 590 | 740 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 | |

| 4 | 300 | 430 | 890 | IPR | .002–.005 | .003–.006 | .004–.007 | .005–.010 | .006–.011 | .007–.013 | .008–.013 | .009–.015 | |

| S | 1 | 70 | 80 | 100 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 |

| 2 | 30 | 70 | 100 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 | |

| 3 | 70 | 80 | 130 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 | |

| 4 | 70 | 80 | 160 | IPR | .001–.002 | .002–.003 | .002–.004 | .002–.004 | .003–.004 | .003–.005 | .004–.006 | .004–.008 | |

<="" td=""> <="" td=""> |  <="" td="" /> <="" td="" /> |

||||||||||||

| Cutting Speed

|

Metric | ||||||||||||

| Range

|

Recommended Feed Rate (f) by Diameter | ||||||||||||

| Material

|

Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 0 | 50 | 65 | 100 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 |

| 1 | 40 | 55 | 80 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 2 | 40 | 55 | 80 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 3 | 40 | 55 | 80 | mm/dev | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,24 | 0,18–0,28 | |

| 4 | 40 | 55 | 80 | mm/dev | 0,05–0,08 | 0,05–0,10 | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,22 | 0,16–0,24 | |

| 5 | 30 | 40 | 60 | mm/dev | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| 6 | 30 | 40 | 60 | mm/dev | 0,03–0,05 | 0,03–0,06 | 0,04–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,14 | 0,12–0,18 | 0,14–0,20 | |

| M | 1 | 30 | 35 | 50 | mm/dev | 0,04–0,07 | 0,05–0,09 | 0,06–0,11 | 0,80–0,13 | 0,09–0,15 | 0,10–0,17 | 0,11–0,20 | 0,12–0,23 |

| 2 | 30 | 40 | 50 | mm/dev | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| 3 | 25 | 30 | 40 | mm/dev | 0,03–0,05 | 0,04–0,08 | 0,05–0,09 | 0,06–0,10 | 0,07–0,12 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | |

| K | 1 | 60 | 90 | 120 | mm/dev | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 |

| 2 | 60 | 80 | 100 | mm/dev | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| 3 | 60 | 90 | 120 | mm/dev | 0,06–0,12 | 0,08–0,14 | 0,10–0,16 | 0,12–0,18 | 0,14–0,20 | 0,16–0,22 | 0,18–0,26 | 0,20–0,30 | |

| N | 1 | 90 | 230 | 270 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 |

| 2 | 90 | 220 | 270 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 3 | 90 | 180 | 225 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| 4 | 90 | 130 | 270 | mm/dev | 0,06–0,13 | 0,08–0,15 | 0,10–0,18 | 0,12–0,25 | 0,15–0,28 | 0,18–0,32 | 0,20–0,34 | 0,22–0,38 | |

| S | 1 | 20 | 25 | 30 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 |

| 2 | 10 | 20 | 30 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 3 | 20 | 25 | 40 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |

| 4 | 20 | 25 | 50 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,06–0,10 | 0,07–0,11 | 0,08–0,13 | 0,09–0,16 | 0,10–0,20 | |