Willkommen

Bestätigen Sie bitte Ihre Präferenzen

Einstellungen aktualisieren

Produktvorschläge

Product Family suggestions

Kennametal steht Ihnen zur Diensten

Hallo, User Name

Das von Ihnen ausgewählte Konto:

Es gibt ein Problem mit Ihrem Konto. Bitte kontaktieren Sie den Kundendienst.

Kundenkonto Konto ändern

Lieferadresse Konto ändern

- Übersicht

- Bestellungen verwalten

- Kanäle verwalten

- Adressbuch

Notifications

Mark all as read- Passwort ändern

- Mein Profil

- Abmelden

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Mehr bekommen, weniger zahlen mit unseren zeitlich begrenzten angeboten. Jetzt bestellen

Kennametal steht Ihnen zur Diensten

Artikel erfolgreich zum Warenkorb hinzugefügt

Warenkorb anzeigen

Warenkorb anzeigen

Lösung bearbeiten

Lösung hinzufügen

Lösungsname:{{SolutionName}}- Produkte

- /

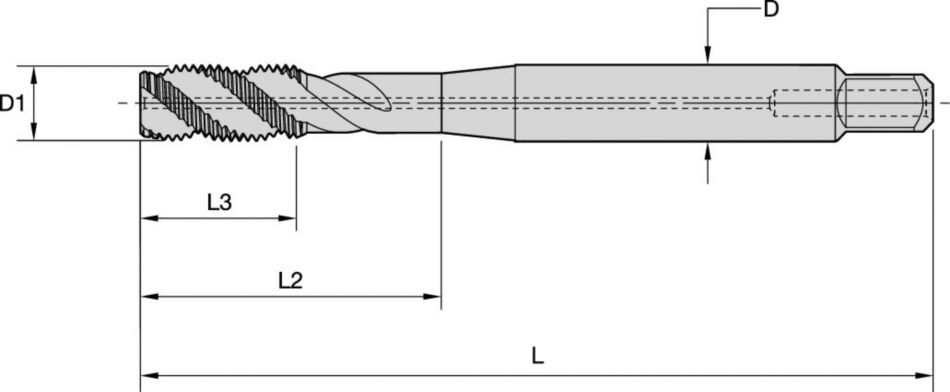

- T631 • Metrisch • DIN 371, 374 und 376 Beyond HSS-E-PM mit Rechtsspirale für Sacklochbohrungen, mit axialen Kühlmittelbohrungen

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

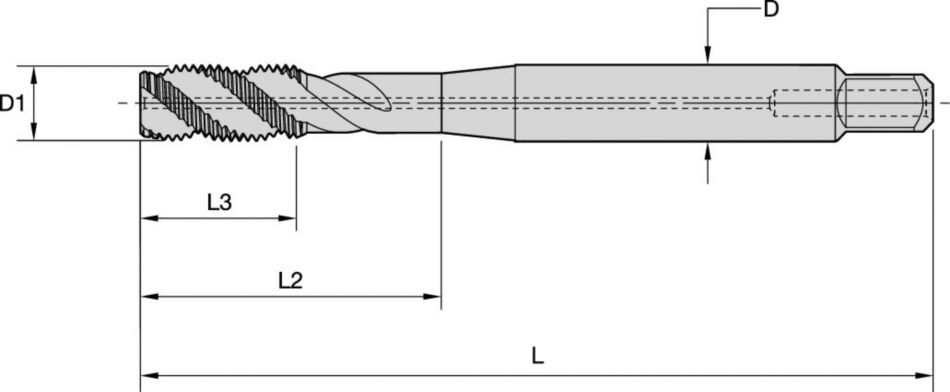

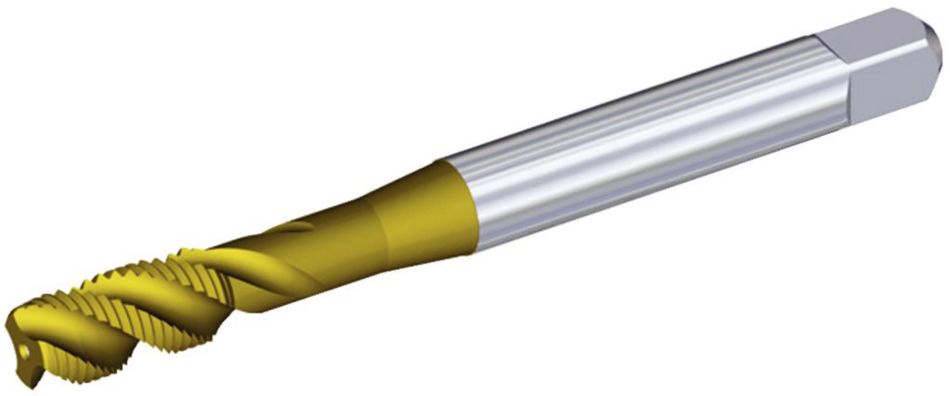

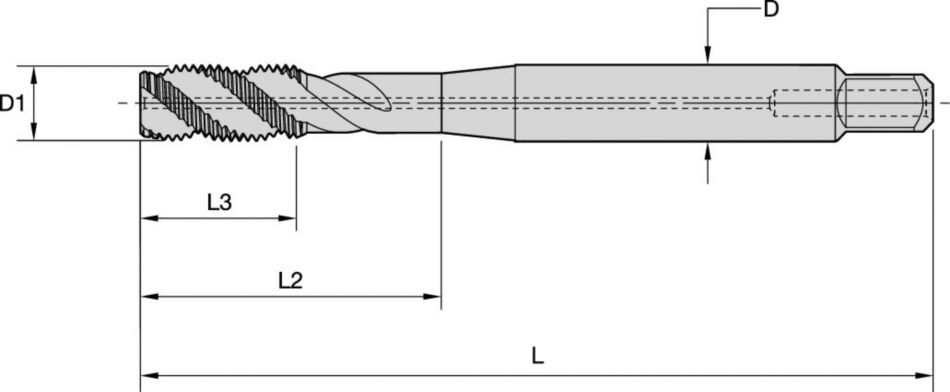

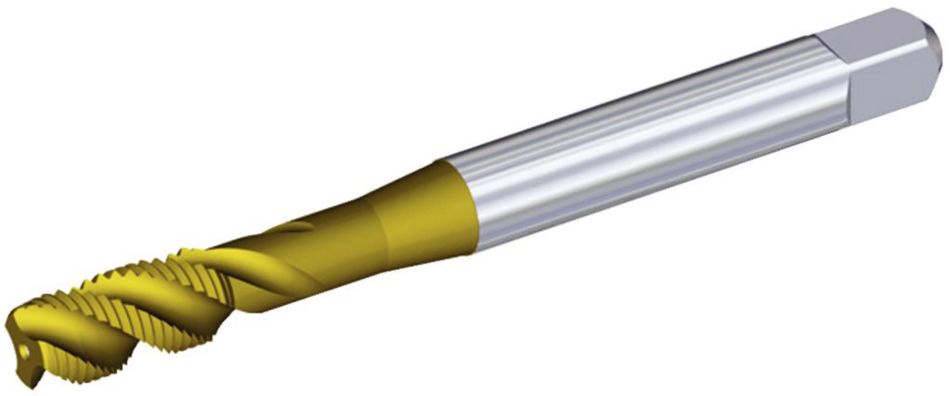

T631 • Metrisch • DIN 371, 374 und 376 Beyond HSS-E-PM mit Rechtsspirale für Sacklochbohrungen, mit axialen Kühlmittelbohrungen

Beyond™ HSS-E-PM Gewindebohrer • Sacklochbohrungen

Features and benefits

- KM6515 TiN + CrC/C für nicht rostenden Stahl.

- KP6525 TiCN + TiN für Stahl.

Uses and application

Gewindedrehen: Sacklochbohrung

Toleranzklasse: 6HX

DIN 371

DIN 374

DIN 376

Anschnitt Form C (2–3)

HSS-E-PM

Innere Kühlmittelzuführung: Axial: Gewindebohren

Herstellerspezifikationen: M

Herstellerspezifikationen: MF

Spiralwinkel Gewindebohrer: 45°