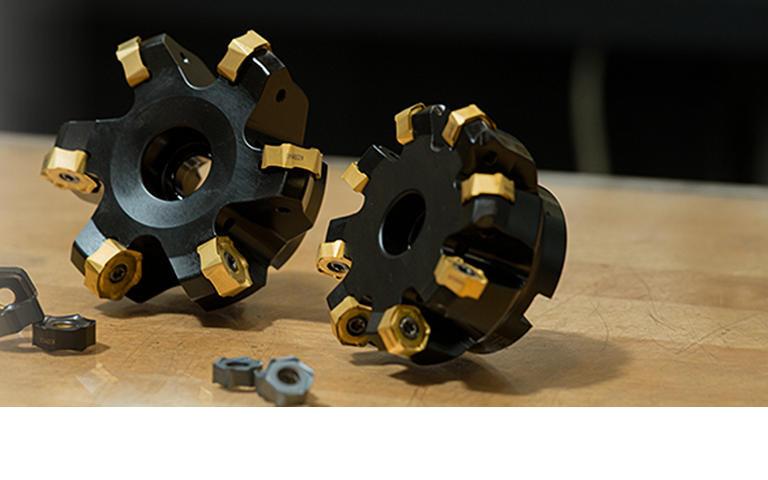

Planfräsen mit 12 echten Schneiden je Wendeschneidplatte

- Die Planfräsplattformen Dodeka Mini, Dodeka und Dodeka MAX™ sind die leistungsstärksten Planfräser auf dem heutigen Markt.

- Zwölf echte Schneiden pro Wendeschneidplatte garantieren niedrige Kosten pro Schneide und eine hohe Produktivität.

- Erreichen Sie mit den Beyond™ Premiumsorten zum Fräsen bis zu 30 % höhere Zerspanungsvolumina, 25 % geringere Schnittkräfte aufgrund ihres weichen Schnittes und eine bis zu 35 % längere Standzeit bei leichter bis schwerer Bearbeitung.