Sortenfertigung:

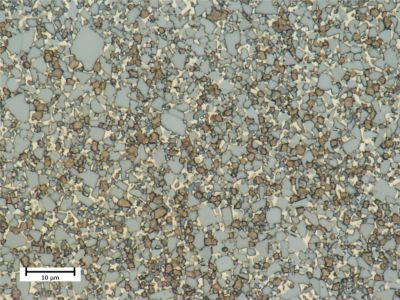

Wenn das WC-Pulver dann mit pulverförmigem Trägermetall, typischerweise Kobalt oder Nickel, sowie anderen Zusätzen gemischt wird, erhalten Sie ein „Sortenpulver“. Jede Sorte enthält unterschiedliche Mengen an WC und Trägermetall und hat eine unterschiedliche Korngröße des WC-Pulvers. Zentrifugen-Verschleißteile sind in der Regel aus 6–10 % Trägermetall und dem Rest WC, mit Korngrößen von unter 1 Mikron bis zu 3 Mikron und mit korrosionsbeständigen Zusätzen.

Formen des Pulvers:

Das Pressen des Sortenpulvers in eine Matrize mit einer Hydraulikpresse ist die wirtschaftlichste Methode für kleinere Teile, die in Massenproduktion produziert werden. Unsere Zentrifugenplatten werden mit dieser Methode hergestellt.

Bei der Herstellung großer oder komplexer Teile wie Ein- und Auslaufdüsen muss das Sortenpulver durch hydrostatischen Druck in „Posten“ verdichtet werden. Unabhängig davon, durch welche der beiden Methoden das Hartmetall verdichtet wurde, ist es noch immer ein sehr weiches, kreideähnliches Material und wird als „Grünling“ bezeichnet. Falls erforderlich, kann dieser Grünling oder Sinterling durch herkömmliche Verfahren wie Drehen, Bohren, Fräsen oder Schleifen geformt werden, um eine „Vorform“ zu schaffen. Wir sind auch in der Lage, Hartmetall-Vorformen per additiver Fertigung zu produzieren.

Sintern:

Die Hartmetall-„Vorform“ wird dann auf ein Tablett gelegt, das in einen Sinterofen geladen und bis zum Schmelzpunkt des Trägermetalls erhitzt wird, der im Allgemeinen bei 2.500 °F bis 2.800 °F liegt. Das Sintern bewirkt, dass das Teil in der linearen Dimension um etwa 20 % und im Volumen um etwa 50 % schrumpft. Nach dem Abkühlen haben Sie einen harten Hartmetall-Rohling.

Schlichten:

Das Hartmetall kann „wie gesintert” verwendet und an Stahl gelötet werden, wie bei unseren Platten. Es kann mit Epoxidharz behandelt für eine bestimmte Auslaufdüse an dem Stahl befestigt werden oder für Komponenten mit kritischer Passform sogar auf genaue Toleranzen feinbearbeitet werden.