Positive Profiling

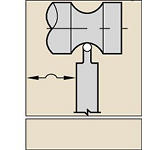

Kennametal PROON positive profiling tool holders offer reliability and precision in heavy-duty turning operations. Designed for use with positive profiling inserts, the PROON holder features an innovative bevel lock mechanism for RCGH or RCMH-K inserts, ensuring rigid clamping and maximum stability during high-performance tasks. With its heavy-duty profiling capability and full 180° cut radius around the insert, the PROON holder delivers unparalleled accuracy and efficiency, even in the most demanding applications. The clear-top design allows for easy monitoring of operations, while the ability to remove the insert without removing the screw streamlines maintenance processes, minimizing downtime. Additionally, the turning toolholder is designed with a square shank.

- P Steel (5)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(5)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(5)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(5)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(5)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(5)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(5)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(5)

- M Stainless Steel (5)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(5)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(5)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(5)

- K Cast Iron (5)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(5)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(5)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(5)

- S High-Temp Alloys (3)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(3)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(3)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(3)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(3)

Facing (6)

Multiple Direction Cutting (6)

Profiling (6)

Turning (6)

- Lightly Interrupted Cut (5)

- Smooth Cut (5)

- 1.0 (5)

- 6.0 in(5)

- 8.0 in(1)

- 152.4 mm(5)

- 203.2 mm(1)

- 0.25 in(3)

- 0.375 in(1)

- 0.5 in(1)

- 6.35 mm(3)

- 9.525 mm(1)

- 12.7 mm(1)

- K313 (1)

- K68 (1)

- KC5010 (3)

- KC850 (5)

- KCP10B (1)

- KCP25C (5)

- KCS10 (3)

- KCU10 (3)

- KCU10B (3)

- N (5)

- 19.05 mm(1)

- 22.225 mm(1)

- 25.4 mm(2)

- 28.575 mm(2)

- 0.75 in(1)

- 0.875 in(1)

- 1.0 in(2)

- 1.125 in(2)

- B (3)

- E (3)

- 1.863 in(1)

- 1.875 in(2)

- 2.323 in(1)

- 2.364 in(1)

- 2.374 in(1)

- 47.32 mm(1)

- 47.625 mm(2)

- 59.004 mm(1)

- 60.046 mm(1)

- 60.3 mm(1)

- H W (5)

- 1.0 in(1)

- 1.25 in(3)

- 1.5 in(2)

- 25.4 mm(1)

- 31.75 mm(3)

- 38.1 mm(2)

- 1.0 in(1)

- 1.25 in(3)

- 1.5 in(2)

- 25.4 mm(1)

- 31.75 mm(3)

- 38.1 mm(2)