Product Similar To :

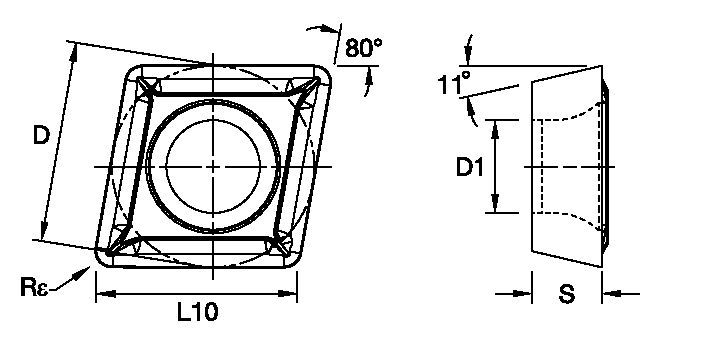

Positive Inserts • CPGT-LF

Screw-On Inserts

Material Number1161906

ISO Catalog IDCPGT060202LFANSI Catalog IDCPGT21505LF

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1161906 |

| ISO Catalog ID | CPGT060202LF |

| ANSI Catalog ID | CPGT21505LF |

| Grade | KC730 |

| [D] Insert IC Size | 6.35 mm |

| [D] Insert IC Size | 0.25 in |

| [L10] Insert Cutting Edge Length | 6.448 mm |

| [L10] Insert Cutting Edge Length | 0.2539 in |

| [S] Insert Thickness | 2.381 mm |

| [S] Insert Thickness | 0.0938 in |

| [Rε] Corner Radius | 0.2 mm |

| [Rε] Corner Radius | 0.008 in |

| [D1] Insert Hole Size | 2.9 mm |

| [D1] Insert Hole Size | 0.114 in |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Grades

KC730

KC730

Features and benefits

- Finishing geometry with light cutting action

- Used in multiple material groups

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use