Product Similar To :

NR • Groove and Turn • Full Radius • Flat Top

Top Notch™ Groove and Turn Inserts

Material Number3387910

ISO Catalog IDNR2M050LANSI Catalog IDNR2M050L

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3387910 |

| ISO Catalog ID | NR2M050L |

| ANSI Catalog ID | NR2M050L |

| Grade | KC5010 |

| Insert Size | 2 |

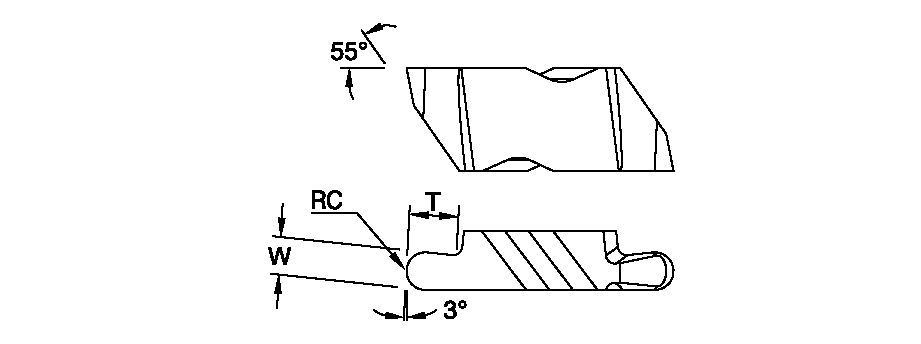

| [W] Cutting Width | 1 mm |

| [W] Cutting Width | 0.0394 in |

| [RC] Corner Radius Center | 0.5 mm |

| [RC] Corner Radius Center | 0.02 in |

| [T] Cuttg Depth | 1.27 mm |

| [T] Cutting Depth | 0.05 in |

Workpiece Materials

- Stainless Steel

- High-Temp Alloys

Grades

KC5010

Composition: An advanced PVD AlTiN coating over a very deformation-resistant unalloyed carbide substrate. The new and improved coating enables speeds to be increased by 50–100%.

Application: The KC5010 grade is ideal for finishing to general machining of most workpiece materials at higher speeds. Excellent for machining most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. It also performs well machining hardened and short chipping materials.

Features and benefits

- KENGold™ PVD, multilayer coating for easy wear-detection

- A positive chipbreaker that delivers very low cutting forces for excellent chip control

- Precision-ground inserts for accurate indexing, resulting in reliability and repeatability

- Improved cutting conditions for tool life, stability and rigidity

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use