Product Similar To:

DCGR • DPGR

Inserts

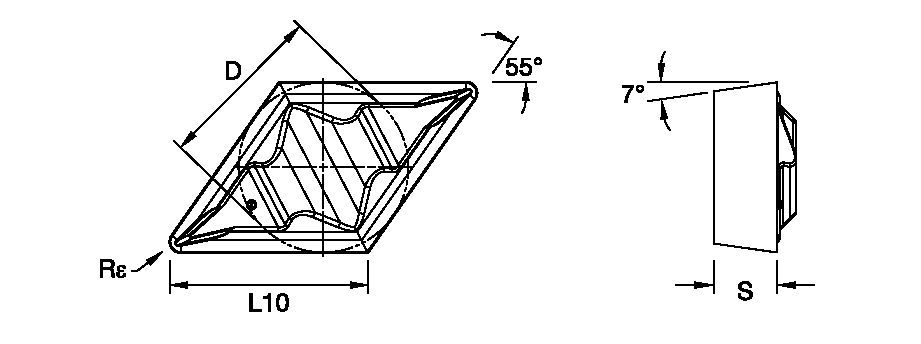

Material Number3643862

ISO Catalog IDDCGR150408ANSI Catalog IDDPGR432

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3643862 |

| ISO Catalog ID | DCGR150408 |

| ANSI Catalog ID | DPGR432 |

| Grade | KD1425 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [L10] Insert Cutting Edge Length | 15.504 mm |

| [L10] Insert Cutting Edge Length | 0.6104 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | 0.1875 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

Workpiece Materials

- Non-Ferrous

Grades

KD1425

Composition: A multimodal PCD grade with a range of grain sizes brazed onto a carbide substrate.

Application: Engineered for extreme abrasion resistance, combined with good edge strength for demanding applications. An ideal choice for high-silicon aluminium alloys, bi-metallic (AL/GCI) materials, MMC, carbon-fibre reinforced plastics, and other abrasive non-metallic materials.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use