Product Similar To:

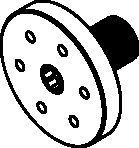

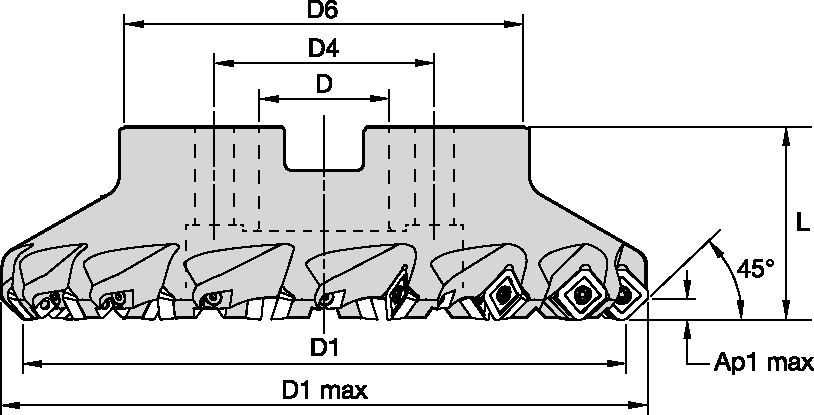

Beyond BLAST™ KSSM™ 45° • 14mm IC • Shell Mills • Metric

Shell Mills

Material Number4137782

ISO Catalog ID100B07RS45SE14BBANSI Catalog ID100B07RS45SE14BB

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Face Milling

Side Milling/Shoulder Milling: Eased Chamfer

Milling - Through Coolant

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 4137782 |

| ISO Catalog ID | 100B07RS45SE14BB |

| ANSI Catalog ID | 100B07RS45SE14BB |

| [D1] Effective Cutting Diameter | 100 mm |

| [D1] Effective Cutting Diameter | 3.937 in |

| [D1MAX] Maximum Cutting Diameter | 113.71 mm |

| [D1MAX] Maximum Cutting Diameter | 4.477 in |

| [D] Adapter / Shank / Bore Diameter | 32 mm |

| [D] Adapter / Shank / Bore Diameter | 1.2598 in |

| [D6] Hub Diameter | 80 mm |

| [D6] Hub Diameter | 3.15 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.97 in |

| [AP1MAX] 1st Maximum Cutting Depth | 6.6 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.26 in |

| Number of Inserts | 7 |

| Weight Kilograms | 1.89 |

| Max RPM | 13000 |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Uses and application

Face Milling

Side Milling/Shoulder Milling: Eased Chamfer

Milling - Through Coolant

Milling - Side and Face

Features and benefits

- Precision Coolant Technology (PCT).

- Coolant delivery exactly to cutting area.

- Increased heat transfer.

- Improved chip control.

- Productivity booster for machining titanium.

- High coolant pressure capabilities.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

Recommended Starting Feeds [mm]

Recommended Starting Feeds [IPT]

Speeds

Recommended Starting Speeds [m/min]

Recommended Starting Speeds [SFM]

Insert Selection

Insert Selection Guide

I have read and accepted the Terms & Conditions of use