Product Similar To:

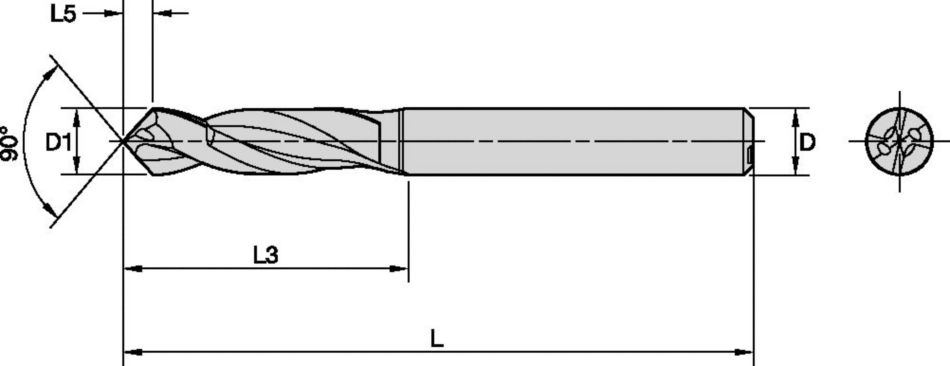

HiPACS Drill • 3 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Drill for CFRP Rivot Hole Machining in Aerospace

Material Number6771200

ISO Catalog IDB536H05558SPFPANSI Catalog IDB536H05558SPFP

- C CFRP Materials

Drilling

Drilling: Stacked Plates

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6771200 |

| ISO Catalog ID | B536H05558SPFP |

| ANSI Catalog ID | B536H05558SPFP |

| Grade | KCC05 |

| [D1] Drill Diameter M | 5.558 mm |

| [D1] Drill Diameter M | 0.2187 in |

| [L] Overall Length | 75 mm |

| [L] Overall Length | 3.6023 in |

| [L3] Flute Length | 33 mm |

| [L3] Flute Length | 1.2992 in |

| [L4] Maximum Drilling Depth | 25 mm |

| [L4] Maximum Drilling Depth | 0.9843 in |

| [L5] Drill Point Length | 2.52 mm |

| [L5] Drill Point Length | 0.0992 in |

| [LS] Shank Length | 42 mm |

| [LS] Shank Length | 1.6535 in |

| [D] Adapter / Shank / Bore Diameter | 6 mm |

| [D] Adapter / Shank / Bore Diameter | 0.2362 in |

Workpiece Materials

- CFRP Materials

Uses and application

Drilling

Drilling: Stacked Plates

Grades

KCC05

Composition: Multilayered CVD diamond-coated, submicron-grain carbide.

Application: First choice for machining carbon-fiber reinforced polymers (CFRPs). This grade offers best wear resistance and highest tool life in most CFRP materials.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| C | 1 | 300 | 390 | 590 | IPR | .002 | .002 | .002 | .002 | .002 | .002 | ||

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 90 | 120 | 180 | mm/r | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | ||

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 90 | 120 | 180 | mm/r | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | ||

| Material | Cutting Speed | Inch | |||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||

| Min | Starting Value | Max | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| C | 1 | 260 | 330 | 490 | IPR | .002 | .002 | .002 | .002 | .002 | .002 |

| Material | Cutting Speed | Metric | |||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||

| Min | Starting Value | Max | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 80 | 100 | 150 | mm/r | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 |

| Material | Cutting Speed | Metric | |||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||

| Min | Starting Value | Max | 6,0 | 8.0 | 10.0 | 12.0 | 16.0 | 20.0 | |||

| C | 1 | 80 | 100 | 150 | mm/r | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 | 0.05~0.20 |

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 90 | 120 | 180 | mm/r | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | ||

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| C | 1 | 300 | 390 | 590 | IPR | .002 | .002 | .002 | .002 | .002 | .002 | ||

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 90 | 120 | 180 | mm/r | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | 0,05 | ||

| Material |  |  | |||||||||||

| Cutting Speed | Inch | ||||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| C | 1 | 300 | 390 | 490 | IPR | .001 | .001 | .001 | .001 | .001 | .001 | ||

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 90 | 120 | 150 | mm/r | 0,03 | 0,03 | 0,03 | 0,03 | 0,03 | 0,03 | ||

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate per Rev | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| C | 1 | 90 | 120 | 150 | mm/r | 0,03 | 0,03 | 0,03 | 0,03 | 0,03 | 0,03 | ||

I have read and accepted the Terms & Conditions of use