Product Similar To:

Rodeka™ IC 10 • KDR..R10... • Weldon End Mills • Inch

Weldon® End Mills

Material Number5154400

ISO Catalog IDKDR100R1003W100L200ANSI Catalog IDKDR100R1003W100L200

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

- H Hardened Materials

- .caption

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Shank - Cylindrical Weldon

Milling - Through Coolant

Pocketing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 5154400 |

| ISO Catalog ID | KDR100R1003W100L200 |

| ANSI Catalog ID | KDR100R1003W100L200 |

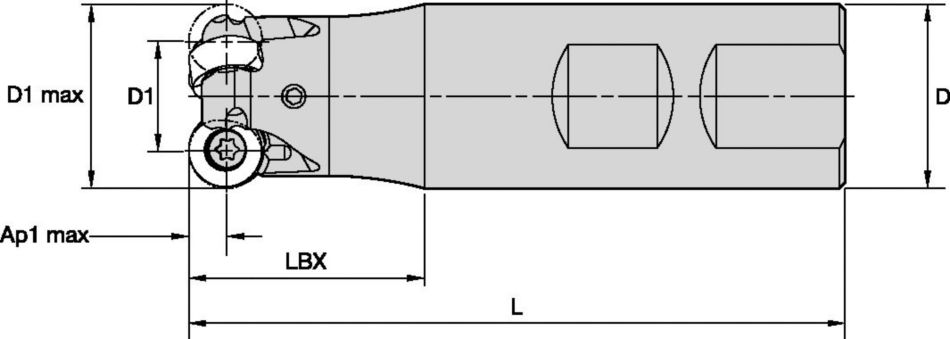

| [D1MAX] Maximum Cutting Diameter | 25.4 mm |

| [D1MAX] Maximum Cutting Diameter | 1 in |

| [D1] Effective Cutting Diameter | 15.4 mm |

| [D1] Effective Cutting Diameter | 0.606 in |

| [D] Adapter / Shank / Bore Diameter | 25.4 mm |

| [D] Adapter / Shank / Bore Diameter | 1 in |

| [L] Overall Length | 108.71 mm |

| [L] Overall Length | 4.28 in |

| [LBX] Body Length Maximum | 50.8 mm |

| [LBX] Body Length Maximum | 2 in |

| [AP1MAX] 1st Maximum Cutting Depth | 4.96 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 0.195 in |

| Number of Inserts | 3 |

| Maximum Ramping Angle | 0.6 |

| Max RPM | 54200 |

| Gage Insert | RN_J10T3M0_N__ |

| Weight Pounds | 0.73 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

- Hardened Materials

- .caption

Uses and application

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Shank - Cylindrical Weldon

Milling - Through Coolant

Pocketing

Features and benefits

- Double-sided round insert with eight indexable positions.

- Anti-rotation features enable higher cutting data and extra stability.

- Pocketing, profiling, ramping, and helical interpolation capabilities.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | .005 | .016 | .028 | .004 | .011 | .020 | .003 | .008 | .015 | .002 | .007 | .013 | .002 | .007 | .012 | .F..LDJ |

| .E..LDJ | .005 | .017 | .030 | .004 | .013 | .021 | .003 | .009 | .016 | .002 | .008 | .014 | .002 | .008 | .013 | .E..LDJ |

| .E..LD | .005 | .017 | .030 | .004 | .013 | .021 | .003 | .009 | .016 | .002 | .008 | .014 | .002 | .008 | .013 | .E..LD |

| .S..GDJ | .009 | .021 | .032 | .007 | .015 | .023 | .005 | .011 | .017 | .004 | .010 | .015 | .004 | .009 | .014 | .S..GDJ |

| .S..GD | .009 | .021 | .032 | .007 | .015 | .023 | .005 | .011 | .017 | .004 | .010 | .015 | .004 | .009 | .014 | .S..GD |

| .S..HD | .009 | .021 | .033 | .007 | .015 | .023 | .005 | .011 | .017 | .004 | .010 | .015 | .004 | .009 | .014 | .S..HD |

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | .006 | .021 | .037 | .005 | .015 | .027 | .003 | .011 | .020 | .003 | .010 | .017 | .003 | .009 | .016 | .F..LDJ |

| .E..LDJ | .006 | .023 | .040 | .005 | .016 | .028 | .003 | .012 | .021 | .003 | .011 | .018 | .003 | .010 | .017 | .E..LDJ |

| .E..LD | .006 | .023 | .040 | .005 | .016 | .028 | .003 | .012 | .021 | .003 | .011 | .018 | .003 | .010 | .017 | .E..LD |

| .S..GDJ | .012 | .027 | .043 | .009 | .019 | .030 | .007 | .014 | .022 | .006 | .013 | .019 | .005 | .012 | .018 | .S..GDJ |

| .S..GD | .012 | .027 | .043 | .009 | .019 | .030 | .007 | .014 | .022 | .006 | .013 | .019 | .005 | .012 | .018 | .S..GD |

| .S..HD | .012 | .028 | .043 | .009 | .020 | .031 | .007 | .015 | .023 | .006 | .013 | .020 | .005 | .012 | .018 | .S..HD |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | .011 | .037 | .067 | .008 | .026 | .047 | .006 | .019 | .034 | .005 | .017 | .030 | .005 | .015 | .027 | .F..LDJ |

| .E..LDJ | .011 | .041 | .072 | .008 | .029 | .050 | .006 | .021 | .037 | .005 | .019 | .032 | .005 | .017 | .029 | .E..LDJ |

| .E..LD | .011 | .041 | .072 | .008 | .029 | .050 | .006 | .021 | .037 | .005 | .019 | .032 | .005 | .017 | .029 | .E..LD |

| .S..GDJ | .021 | .048 | .077 | .015 | .034 | .053 | .011 | .025 | .039 | .010 | .022 | .034 | .009 | .020 | .031 | .S..GDJ |

| .S..GD | .021 | .048 | .077 | .015 | .034 | .053 | .011 | .025 | .039 | .010 | .022 | .034 | .009 | .020 | .031 | .S..GD |

| .S..HD | .021 | .049 | .078 | .015 | .035 | .054 | .011 | .026 | .040 | .010 | .022 | .034 | .009 | .020 | .031 | .S..HD |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LDJ | .008 | .026 | .048 | .006 | .019 | .034 | .004 | .014 | .025 | .004 | .012 | .022 | .004 | .011 | .020 | .F..LDJ |

| .E..LDJ | .008 | .029 | .051 | .006 | .021 | .036 | .004 | .016 | .027 | .004 | .014 | .023 | .004 | .012 | .021 | .E..LDJ |

| .E..LD | .008 | .029 | .051 | .006 | .021 | .036 | .004 | .016 | .027 | .004 | .014 | .023 | .004 | .012 | .021 | .E..LD |

| .S..GDJ | .015 | .035 | .054 | .011 | .025 | .038 | .008 | .018 | .028 | .007 | .016 | .025 | .007 | .015 | .023 | .S..GDJ |

| .S..GD | .015 | .035 | .054 | .011 | .025 | .038 | .008 | .018 | .028 | .007 | .016 | .025 | .007 | .015 | .023 | .S..GD |

| .S..HD | .015 | .035 | .055 | .011 | .025 | .039 | .008 | .019 | .029 | .007 | .016 | .025 | .007 | .015 | .023 | .S..HD |

Speeds

Recommended Starting Speeds [SFM]

| Material Group | KC422M | KC510M | KCK15 | KC520M | KCPM20 | KC522M | KC725M | KCMP30 | KCPK30 | |||||||||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 2170 | 1910 | 1760 | 1300 | 1130 | 1060 | 1030 | 900 | 840 | 1780 | 1560 | 1450 | 1780 | 1560 | 1450 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 1340 | 1210 | 1090 | 1080 | 950 | 790 | 860 | 760 | 640 | 1100 | 1000 | 900 | 1100 | 1000 | 900 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 1210 | 1090 | 1000 | 1000 | 840 | 700 | 790 | 670 | 550 | 1000 | 900 | 820 | 1000 | 900 | 820 | |

| 4 | – | – | – | 960 | 780 | 660 | – | – | – | – | – | – | 910 | 840 | 760 | 890 | 730 | 590 | 710 | 590 | 470 | 740 | 690 | 620 | 740 | 690 | 620 | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | 1090 | 980 | 900 | 730 | 660 | 590 | 590 | 530 | 470 | 1020 | 910 | 830 | 1020 | 910 | 830 | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | 760 | 660 | 570 | 650 | 490 | 400 | 520 | 400 | 310 | 620 | 540 | – | 620 | 540 | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | 880 | 790 | 680 | 800 | 710 | 650 | 670 | 590 | 540 | 820 | 720 | 620 | 820 | 720 | 620 |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | 800 | 700 | 620 | 730 | 620 | 520 | 610 | 520 | 430 | 730 | 640 | 550 | 730 | 640 | 550 | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | 640 | 570 | 490 | 550 | 480 | 370 | 460 | 400 | 310 | 570 | 520 | 460 | 570 | 520 | 460 | |

| K | 1 | – | – | – | 1150 | 1040 | 940 | 1660 | 1510 | 1340 | 1060 | 960 | 850 | 1420 | 1280 | 1150 | 900 | 820 | 720 | – | – | – | – | – | – | 1160 | 1050 | 940 |

| 2 | – | – | – | 910 | 820 | 760 | 1310 | 1170 | 1090 | 830 | 740 | 700 | 1130 | 1010 | 920 | 710 | 640 | 590 | – | – | – | – | – | – | 920 | 830 | 760 | |

| 3 | – | – | – | 770 | 680 | 620 | 1100 | 980 | 900 | 700 | 620 | 560 | 950 | 840 | 780 | 590 | 530 | 480 | – | – | – | – | – | – | 770 | 690 | 640 | |

| N | 1 | 4220 | 3720 | 3440 | 2520 | 2240 | 2060 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 3720 | 3440 | 3000 | 2280 | 2100 | 1920 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | 140 | 120 | 100 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | 140 | 120 | 100 | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 200 | 160 | 110 | 180 | 140 | 100 | 180 | 140 | 100 | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 280 | 200 | 140 | 240 | 180 | 120 | 240 | 180 | 120 | – | – | – | |

| H | 1 | – | – | – | 630 | 510 | 360 | – | – | – | – | – | – | 550 | 460 | 370 | 470 | 360 | 280 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Insert Selection

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..LDJ | KC725M | .S..GD | KCPM40 | .S..HD | KCPM40 |

| P3–P4 | .S..GD | KCPK30 | .S..HD | KCPK30 | .S..HD | KCPM40 |

| P5–P6 | .E..LDJ | KC725M | .S..GDJ | KC725M | .S..HD | KC725M |

| M1–M2 | .E..LDJ | KC522M | .E..LDJ | KCSM40 | .S..GDJ | KC522M |

| M3 | .E..LDJ | KCSM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| K1–K2 | .S..HD | KC520M | .S..HD | KC520M | .S..HD | KCK15 |

| K3 | .S..HD | KC520M | .S..HD | KCK15 | .S..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC422M | .F..LDJ | KC422M | .S..GD | KC510M |

| N3 | – | – | – | – | – | – |

| S1–S2 | .E..LDJ | KC725M | .S..GDJ | KC725M | .S..HD | KC725M |

| S3 | .E..LDJ | KCSM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| S4 | .E..LDJ | KC522M | .E..LDJ | KCSM40 | .S..GDJ | KC522M |

| H1 | .S..GD | KC510M | .S..GD | KC510M | – | – |

I have read and accepted the Terms & Conditions of use