Hydraulic chucks are essential tools in precision machining, offering high accuracy and stability.

They provide consistent clamping force, excellent vibration damping, and ease of use. This guide explores the mechanics, advantages, and best practices for extending the tool life of hydraulic chucks.

How do Hydraulic Chucks Work?

Hydraulic chucks operate on the principle of hydraulic pressure. They consist of a cylindrical body with an internal chamber filled with hydraulic fluid. When the clamping screw is tightened, it compresses the hydraulic fluid, which in turn expands the chamber and applies uniform pressure around the shank of the cutting tool. This ensures a secure and precise grip.

Key Components

- Clamping Bore: The internal cavity where the cutting tool is inserted.

- Hydraulic Chamber: Filled with hydraulic fluid, this chamber expands to apply pressure.

- Clamping Screw: Tightened to compress the hydraulic fluid and create the clamping force.

- Stop Pin/Stop Screw: Ensures the tool is inserted to the correct depth.

- Hex Wrench: Used for adjusting the tool length and tightening the clamping screw.

Advantages of Hydraulic Chucks

- Hydraulic chucks provide excellent runout accuracy, typically within 3 microns. This precision is crucial for high-speed machining and achieving fine surface finishes.

- The hydraulic fluid acts as a damper, reducing vibrations during machining. This leads to better surface quality and longer tool life.

- The clamping and unclamping process is easy and straightforward for the user, requiring only a hex wrench.

- The hydraulic mechanism ensures that the clamping force provides uniform pressure around the tool shank, preventing tool slippage and ensuring consistent performance.

- Suitable for a wide range of applications, from high-speed milling to drilling and reaming.

Step-by-Step Guide for Hydraulic Chuck Longevity

Step 1: Cleanliness is Key

Before using your hydraulic chuck, remove all grease from both the chuck and the cutting tools. This step is crucial to prevent slippage and ensure a secure grip.

Step 2: Insert the Cutting Tool

Carefully insert the cutting tool into the clamping bore. Push it in as far as the stop pin or stop screw will allow. This ensures the tool is properly seated and ready for adjustment.

Step 3: Adjust the Cutting Tool Length

Using a hex wrench, adjust the cutting tool length. Make sure the tool is positioned correctly for your specific machining needs.

Step 4: Tighten the Clamping Screw

Always hand-tighten the clamping screw with a hex wrench until you reach the stop limit. Never attempt to adjust the stop pin while the hydraulic chuck is in the clamping position, as this can damage the chuck and compromise safety.

Step 5: Accuracy and Shanks

For the best accuracy, use a round shank with h6 tolerance and no bushing. Weldon shanks can be gripped without reducer collets, up to a maximum diameter of ¾” (20 mm). However, it is recommended to use reducer collets for all flatted shanks to ensure a secure and precise grip.

By following these steps, you can maintain the integrity of your hydraulic chuck and cutting tools, ensuring precise and efficient machining operations.

Kennametal Hydraulic Chucks

Ready to take your machining to the next level? Start with these expert hydraulic chuck guidelines and take a look at some of our high-performance chucks including our HSK63A line.

Related Articles

- Kennametal Showcases Innovations Globally Kennametal has been taking the spotlight globally by showcasing the latest innovations at tradeshows including IMTS Chicago, AMB Stuttgart, & JIMTOF Tokyo.Kennametal has been taking the spotlight globally by showcasing the latest innovations at tradeshows including IMTS Chicago, AMB Stuttgart, & JIMTOF Tokyo.

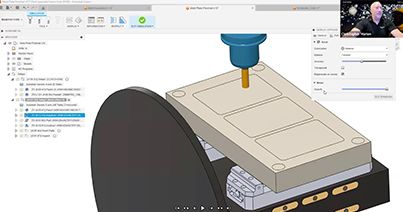

- Webinar: Unlock Efficiency with Autodesk Fusion and Kennametal Tooling SolutionsDiscover how to import Kennametal tooling data into Autodesk Fusion and optimize your manufacturing processes with our in-depth webinar.Discover how to import Kennametal tooling data into Autodesk Fusion and optimize your manufacturing processes with our in-depth webinar.