- Chips From the Real World – KOR™5 Solid Carbide End MillLearn more about how Kennametal's KOR5 solid carbide end mills, helped one customer save over 3 minutes of machining time per part. Watch now!Learn more about how Kennametal's KOR5 solid carbide end mills, helped one customer save over 3 minutes of machining time per part. Watch now!

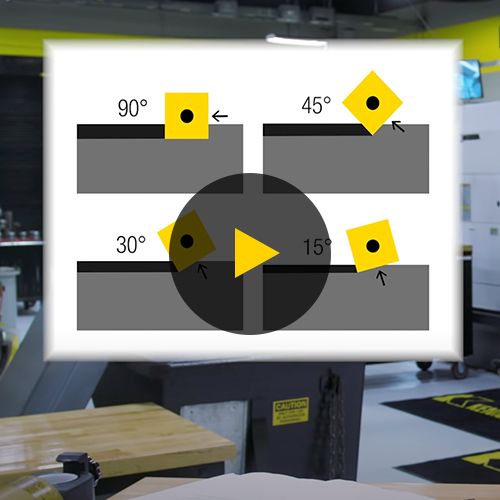

- Tech Tip: Indexable Milling Lead Angle and Cutting ForcesWhen it comes to indexable milling, one of the main decisions is choosing a lead angle. Watch this Kennametal tech tip to learn more.When it comes to indexable milling, one of the main decisions is choosing a lead angle. Watch this Kennametal tech tip to learn more.

- KCFM 45 - Face Mill for Cast Iron Fine FinishingJoin us to take a closer look at the features and benefits of Kennametal's KCFM 45 indexable milling cutter designed for cast-iron finishing. Watch now.Join us to take a closer look at the features and benefits of Kennametal's KCFM 45 indexable milling cutter designed for cast-iron finishing. Watch now.

- Tech Tip: Indexable Milling Lead Angle and Depth of CutWhen choosing a lead angle for your indexable mill, it's important to remember that it will affect the tool's depth of cut capability. Watch now to learn more.When choosing a lead angle for your indexable mill, it's important to remember that it will affect the tool's depth of cut capability. Watch now to learn more.

- Tech Tip: Insert Screw MaintenanceDon't forget about the little guy who holds it all together. Insert screws play a key role in the performance of milling cutters. Watch now to learn more.Don't forget about the little guy who holds it all together. Insert screws play a key role in the performance of milling cutters. Watch now to learn more.

- Tech Tip: Increase Indexable Milling Insert LifeTech Tips: The milling pros at Kennametal show you how to increase indexable milling insert life and improve productivity with our expert tips and solutions. Watch Now!Tech Tips: The milling pros at Kennametal show you how to increase indexable milling insert life and improve productivity with our expert tips and solutions. Watch Now!

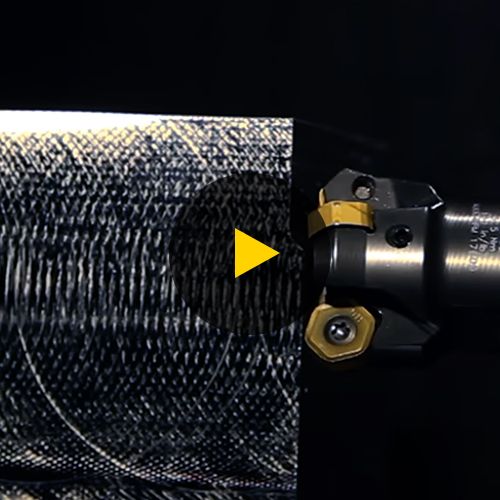

- Machining Two Materials Simultaneously with Mill 4-12KTKennametal's versatile Mill 4-12KT covers many shoulder milling applications. Watch Mill 4-12KT cut a block of steel and a block of cast iron at the same time!Kennametal's versatile Mill 4-12KT covers many shoulder milling applications. Watch Mill 4-12KT cut a block of steel and a block of cast iron at the same time!

- Tech Tip: Selecting the Right Edge Preps for MillingWhen choosing an insert's edge prep, it's important to know the material & cutting conditions of the application. Watch to learn more from Kennametal's experts.When choosing an insert's edge prep, it's important to know the material & cutting conditions of the application. Watch to learn more from Kennametal's experts.

- Chips From the Real World – HARVI I TEChallenge: Create 19 35mm holes per workpiece with 50 workpieces per batch. Solution: Kennametal's HARVI I TE solid carbide end mill. Watch it in action!Challenge: Create 19 35mm holes per workpiece with 50 workpieces per batch. Solution: Kennametal's HARVI I TE solid carbide end mill. Watch it in action!

- How to Center a Boring BarIn turning applications, it's important for the tool to be centered to ensure proper cutting. Learn how to center a boring bar using a digital angle finder.In turning applications, it's important for the tool to be centered to ensure proper cutting. Learn how to center a boring bar using a digital angle finder.

- KOR™ 5 High Velocity Aluminum RoughingLearn more about Kennametal's King of Roughing End Mill. Watch as we compare Kennametal's KOR 5 5-Flute End Mill and MaxiMet 3-Flute End Mill cutting aluminum.Learn more about Kennametal's King of Roughing End Mill. Watch as we compare Kennametal's KOR 5 5-Flute End Mill and MaxiMet 3-Flute End Mill cutting aluminum.

- Save Time & Increase Productivity with First ChoiceKennametal's First Choice tooling covers 80 percent of your daily applications with just a handful of versatile tools. Watch the video to learn more.Kennametal's First Choice tooling covers 80 percent of your daily applications with just a handful of versatile tools. Watch the video to learn more.

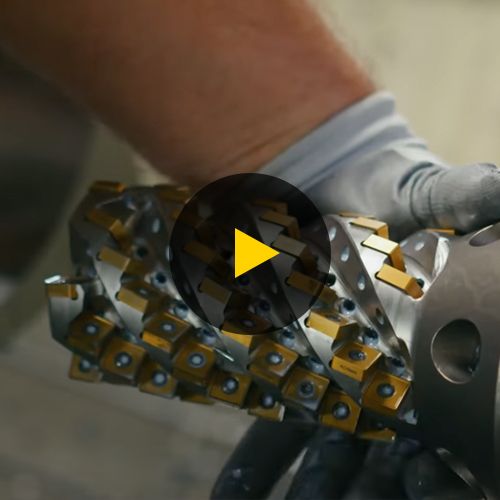

- Milling Titanium Ti6Al-4V with 8 Cutting Edges per InsertWatch Kennametal's indexable helical milling cutter, the HARVI Ultra 8X, mill steel & titanium with 8 cutting edges per insert.Watch Kennametal's indexable helical milling cutter, the HARVI Ultra 8X, mill steel & titanium with 8 cutting edges per insert.

- Increase Productivity with 12 True Cutting Edges Per Insert | With Dodeka & First ChoiceKennametal’s Dodeka face mill has 12 true cutting edges per insert for increased productivity and lower cost per edge. Learn more about this First Choice tool!Kennametal’s Dodeka face mill has 12 true cutting edges per insert for increased productivity and lower cost per edge. Learn more about this First Choice tool!

- HARVI I TE – The Magic Solid End MillLearn more about Kennametal’s HARVI I TE solid carbide end mill, and watch it perform side milling, slotting, plunging, and ramping applications in 4140 steel.Learn more about Kennametal’s HARVI I TE solid carbide end mill, and watch it perform side milling, slotting, plunging, and ramping applications in 4140 steel.

- The Sandwich Cut – HARVI I TENot that you need to do this, but Kennametal’s HARVI I TE can slot four materials at once: steel, stainless steel, titanium, and aluminum. Watch now!Not that you need to do this, but Kennametal’s HARVI I TE can slot four materials at once: steel, stainless steel, titanium, and aluminum. Watch now!

- HPX Drill - Solid Carbide Drill for SteelsLearn more about Kennametal’s solid carbide drill for steels, the HPX drill, and see it drill 5xD blind holes in a block of 4140 steel. Watch now!Learn more about Kennametal’s solid carbide drill for steels, the HPX drill, and see it drill 5xD blind holes in a block of 4140 steel. Watch now!

- HPR Drill | Solid Carbide Drill for Cast IronKennametal’s solid carbide HPR drill for cast iron is made for high speed, high feed drilling with maximum hole straightness and hole quality. Watch now!Kennametal’s solid carbide HPR drill for cast iron is made for high speed, high feed drilling with maximum hole straightness and hole quality. Watch now!

- Introducing GOtip | KenTIP FS GTP Insert Kennametal’s KenTIP FS GTP insert with the GOdrill point design is good for universal applications in steel, stainless steel, & cast iron. Watch to learn more!Kennametal’s KenTIP FS GTP insert with the GOdrill point design is good for universal applications in steel, stainless steel, & cast iron. Watch to learn more!

- PCD Tooling for Aluminum MachiningPCD tool's high speeds & feeds enable the highest productivity in aluminum machining. Watch Kennametal PCD tooling perform 10 operations in under 2 minutes.PCD tool's high speeds & feeds enable the highest productivity in aluminum machining. Watch Kennametal PCD tooling perform 10 operations in under 2 minutes.

- HARVI™ I TE Ball-Nose End MillThe HARVI I TE ball nose end mill is designed with proprietary features, like the rippled relief, for maximum productivity in roughing & finishing. Watch now!The HARVI I TE ball nose end mill is designed with proprietary features, like the rippled relief, for maximum productivity in roughing & finishing. Watch now!

- HPX Drill and GOdrill™ | CNC Machine "Golfing"Kennametal's versatile GOdrill and material-specific HPX drill go head-to-head, drilling 4140 steel while using a golf ball to measure vibrations. Watch now!Kennametal's versatile GOdrill and material-specific HPX drill go head-to-head, drilling 4140 steel while using a golf ball to measure vibrations. Watch now!

- HPR Drills Solid Carbide Drills | Cross-Hole CrazinessWe're putting the HPR drill to the test by drilling a sequence of cross-holes in a cast iron block. Can it overcome the unstable conditions? Let's find out!We're putting the HPR drill to the test by drilling a sequence of cross-holes in a cast iron block. Can it overcome the unstable conditions? Let's find out!

- Romicron High Performance Fine Boring SystemMake manual & automated diameter adjustments one micron at a time with Kennametal’s Romicron fine boring system. Increase productivity & performance! Watch now!Make manual & automated diameter adjustments one micron at a time with Kennametal’s Romicron fine boring system. Increase productivity & performance! Watch now!

- Mill 4-12KT Indexable Mill | Cutting "Swiss Cheese"Kennametal's Mill 4-12KT indexable mill is a staple of stability and strength and handles even the most severely interrupted cuts with ease.Kennametal's Mill 4-12KT indexable mill is a staple of stability and strength and handles even the most severely interrupted cuts with ease.

- Dynamic Milling vs. Conventional MillingKOR series end mills provide high productivity & tool life in multiple materials. Watch as we compare tools designed for dynamic & conventional milling.KOR series end mills provide high productivity & tool life in multiple materials. Watch as we compare tools designed for dynamic & conventional milling.

For US customers, a tariff surcharge will be added to your order for metal cutting products.