Product Similar To:

Drill Fix™ DFSP™ • MD Inserts

Drill Fix™ DFSP™ • MD Inserts

Material Number5534238

ISO Catalog IDSPPX120408MDANSI Catalog IDSPPX120408MD

- M Stainless Steel

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 5534238 |

| ISO Catalog ID | SPPX120408MD |

| ANSI Catalog ID | SPPX120408MD |

| Grade | KCU40 |

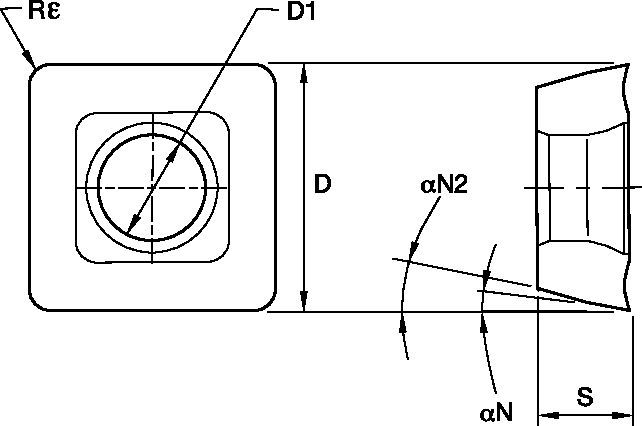

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [D1] Insert Hole Size | 4.6 mm |

| [D1] Insert Hole Size | 0.1811 in |

| [S] Insert Thickness | 4.763 mm |

| [S] Insert Thickness | 0.1875 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [GAA] Insert Rake Angle | 16 |

| [Clearance Angle Major | 7 |

| Clearance Angle Major Second | 11 |

Workpiece Materials

- Stainless Steel

Grades

KCU40

Multilayered PVD TiN-TiAlN-coated fine-grain carbide, offering

highest wear resistance in steel, stainless steel, cast iron, and high-temp alloys.

Features and benefits

- Four cutting edges per insert

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Metric | |||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Cutting Speed | Recommended Feed Rate (fz) by Diameter | |||||||||

| Range | |||||||||||||||

| Min | Starting Value | Max | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| P | 1 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | MD | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | FP | KCPK10 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU25 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | MD | KC7140 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed | Metric | ||||||||||||||

| Range | Recommended Feed Rate (fz) by Diameter | ||||||||||||||

| Material | condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | SPGX05 DFTX2 14,00-17,49 | SPGX06 DFT03 17,50-21,99 | SPGX07 DFT05 22.00-25,99 | SPGX09 DFT05 26.00-32,99 | SPGX12 DFT06/..07 33,00-43,99 | SPGX15 DFT07/..09 44,00-55,00 | |

| P | 1 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 |

| 1 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 1 | U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | MD | KCPK10 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 2 | S | I | MD | KC7140 | 310 | 325 | 360 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 2 | U | O | FP | KCU25 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | U | I | MD | KC7140 | 200 | 215 | 230 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | O | HP | KCU40 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | MD | KC7140 | 130 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | MD | KCPK10 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 3 | S | I | MD | KC7140 | 260 | 285 | 320 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 3 | U | O | FP | KCU25 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | U | I | MD | KC7140 | 180 | 195 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | O | HP | KCU40 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | MD | KC7140 | 110 | 120 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | S | O | FP | KCPK10 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 4 | S | I | MD | KC7140 | 220 | 250 | 300 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 4 | U | O | HP | KCU25 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | U | I | MD | KC7140 | 150 | 180 | 220 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | O | HP | KCU40 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | I | MD | KC7140 | 90 | 110 | 140 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 5 | S | I | MD | KC7140 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 5 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | U | I | MD | KC7140 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | I | MD | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | S | O | HP | KCU25 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 6 | S | I | MD | KC7140 | 180 | 200 | 220 | mm/r | 0,06–0,11 | 0,08–0,14 | 0,10–0,18 | 0,14–0,25 | 0,16–0,30 | 0,18–0,30 | |

| 6 | U | O | HP | KCU40 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | U | I | MD | KC7140 | 120 | 135 | 150 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | I | O | HP | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 6 | I | I | MD | KC7140 | 70 | 85 | 100 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| Metric | |||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Cutting Speed | Recommended Feed Rate (fz) by Diameter | |||||||||

| Range | |||||||||||||||

| Min | Starting Value | Max | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| M | 1 | S | O | FP | KCU25 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | FP | KCU25 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU25 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | ||

| I | MD | KC7140 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed | |||||||||||||||

| Range | Recommended Feed Rate (fz) by Diameter | ||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| M | 1 | S | O | FP | KCU25 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 |

| 1 | S | I | MD | KC7140 | 150 | 190 | 230 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 1 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 1 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 1 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 2 | S | O | FP | KCU25 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | S | I | MD | KC7140 | 150 | 180 | 210 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | O | MD | KCU40 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 2 | U | I | MD | KC7140 | 100 | 130 | 160 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 2 | I | O | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 2 | I | I | MD | KC7140 | 60 | 80 | 100 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 3 | S | O | HP | KCU25 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | S | I | HP | KC7140 | 100 | 130 | 160 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | O | HP | KCU40 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 3 | U | I | HP | KC7140 | 80 | 110 | 140 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,20 | |

| 3 | I | O | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| 3 | I | I | MD | KC7140 | 50 | 70 | 90 | mm/r | 0,03–0,05 | 0,04–0,07 | 0,05–0,09 | 0,07–0,13 | 0,08–0,16 | 0,10–0,18 | |

| Metric | |||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Cutting Speed | Recommended Feed Rate (fz) by Diameter | |||||||||

| Range | |||||||||||||||

| Min | Starting Value | Max | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| K | 1 | S | O | FP | KCPK10 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| I | HP | KCU40 | |||||||||||||

| U | O | FP | KCU25 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | FP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 2 | S | O | FP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| N | 1 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06-0,08 | 0,06-0,10 | 0,08-0,12 | 0,10-0,16 | 0,12-0,021 | 0,14-0,024 |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 2 | S | O | LP | KCU40 | 150 | 180 | 210 | mm/r | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 3 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06-0,08 | 0,06-0,10 | 0,08-0,12 | 0,10-0,16 | 0,12-0,021 | 0,14-0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05-0,07 | 0,06-0,08 | 0,07-0,10 | 0,05-0,10 | 0,06-0,013 | 0,08-0,014 | ||

| I | DS | KCU40 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed | |||||||||||||||

| Range | Recommended Feed Rate (fz) by Diameter | ||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| K | 1 | S | O | FP | KCPK10 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| 1 | S | I | HP | KCU40 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 1 | U | O | FP | KCU25 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | I | HP | KC7140 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | I | O | FP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | HP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | FP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | S | I | HP | KCU40 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | I | HP | KC7140 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| Metric | |||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Cutting Speed | Recommended Feed Rate (fz) by Diameter | |||||||||

| Range | |||||||||||||||

| Min | Starting Value | Max | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| K | 1 | S | O | FP | KCPK10 | 200 | 240 | 300 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| I | HP | KCU40 | |||||||||||||

| U | O | FP | KCU25 | 120 | 155 | 200 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | FP | KC7140 | 80 | 100 | 125 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 2 | S | O | FP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| 3 | S | O | HP | KCPK10 | 180 | 220 | 260 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 110 | 140 | 170 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 80 | 100 | 120 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | ||

| I | HP | KC7140 | |||||||||||||

| N | 1 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 2 | S | O | LP | KCU40 | 150 | 180 | 210 | mm/r | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| 3 | S | O | LP | KCU40 | 150 | 190 | 230 | mm/r | 0,06–0,08 | 0,06–0,10 | 0,08–0,12 | 0,10–0,16 | 0,12–0,021 | 0,14–0,024 | |

| I | DS | KCU40 | |||||||||||||

| U | O | LP | KCU40 | 100 | 130 | 160 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,016 | ||

| I | DS | KCU40 | |||||||||||||

| I | O | LP | KCU40 | 60 | 80 | 100 | mm/r | 0,05–0,07 | 0,06–0,08 | 0,07–0,10 | 0,05–0,10 | 0,06–0,013 | 0,08–0,014 | ||

| I | DS | KCU40 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed | |||||||||||||||

| Range | Recommended Feed Rate (fz) by Diameter | ||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| N | 1 | S | O | HP | KCPK10 | 350 | 500 | 650 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 |

| 1 | S | I | HP | KMF | 350 | 500 | 650 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 1 | U | O | HP | KCU40 | 300 | 400 | 500 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | U | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 1 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 1 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | S | O | HP | KCPK10 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | S | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 2 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 2 | I | O | HP | KCU40 | 175 | 250 | 325 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 2 | I | I | HP | KMF | 175 | 250 | 325 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | S | O | HP | KCPK10 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | S | I | HP | KMF | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 3 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 3 | I | O | HP | KCU40 | 150 | 250 | 350 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 3 | I | I | HP | KMF | 150 | 250 | 350 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | S | O | HP | KCU25 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 4 | S | I | HP | KC7140 | 300 | 400 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 4 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 4 | U | I | HP | KC7140 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 4 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 4 | I | I | HP | KC7140 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | S | O | HP | KCU40 | 400 | 450 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 5 | S | I | HP | KMF | 400 | 450 | 500 | mm/r | 0,07–0,12 | 0,10–0,16 | 0,12–0,20 | 0,16–0,28 | 0,18–0,32 | 0,20–0,34 | |

| 5 | U | O | HP | KCU40 | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 5 | U | I | HP | KMF | 250 | 350 | 450 | mm/r | 0,05–0,09 | 0,06–0,12 | 0,08–0,15 | 0,12–0,20 | 0,14–0,25 | 0,16–0,28 | |

| 5 | I | O | HP | KCU40 | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| 5 | I | I | HP | KMF | 200 | 300 | 400 | mm/r | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | 0,09–0,15 | 0,11–0,18 | 0,13–0,25 | |

| Metric | |||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Cutting Speed | Recommended Feed Rate (fz) by Diameter | |||||||||

| Range | |||||||||||||||

| Min | Starting Value | Max | Ø | SPGX05 DFTX2 14–17,49 | SPGX06 DFT03 17,5–21,99 | SPGX07 DFT05 22,00–25,99 | SPGX09 DFT05 26,00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | ||||||

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | ||

| I | MD | KC7140 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed | |||||||||||||||

| Range | Recommended Feed Rate (fz) by Diameter | ||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | SPGX05 DFTX2 14,00–17,49 | SPGX06 DFT03 17,50–21,99 | SPGX07 DFT05 22.00–25,99 | SPGX09 DFT05 26.00–32,99 | SPGX12 DFT06/..07 33,00–43,99 | SPGX15 DFT07/..09 44,00–55,00 | |

| S | 1 | S | O | HP | KCU40 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 |

| 1 | S | I | MD | KC7140 | 60 | 70 | 75 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 1 | U | O | HP | KCU40 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | U | I | MD | KC7140 | 40 | 50 | 60 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 1 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | S | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 2 | S | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 2 | U | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | U | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | I | O | HP | KCU40 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 2 | I | I | MD | KC7140 | 25 | 30 | 40 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 3 | S | I | MD | KC7140 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 3 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | U | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 3 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | S | O | HP | KCU40 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 4 | S | I | MD | KC7140 | 70 | 80 | 90 | mm/r | 0,03–0,06 | 0,04–0,08 | 0,05–0,10 | 0,08–0,12 | 0,10–0,15 | 0,12–0,18 | |

| 4 | U | O | HP | KCU40 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | U | I | MD | KC7140 | 50 | 60 | 70 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | I | O | HP | KCU40 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

| 4 | I | I | MD | KC7140 | 30 | 40 | 50 | mm/r | 0,02–0,03 | 0,02–0,04 | 0,03–0,05 | 0,04–0,06 | 0,05–0,08 | 0,06–0,10 | |

I have read and accepted the Terms & Conditions of use