Product Similar To:

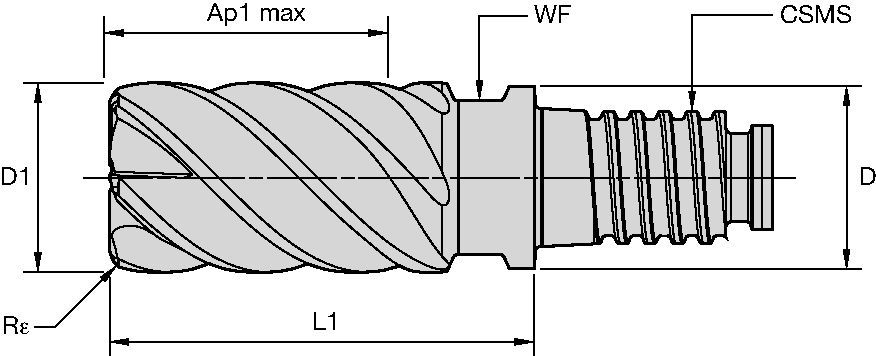

DUO-LOCK™ • KenCut™ FF • Radiused • 6 Flutes • Metric

Modular End Milling • FMDF Style

Material Number6127311

ISO Catalog IDFMDF2000X6CQFANSI Catalog IDFMDF2000X6CQF

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 6

Helix Angle: 45°

Corner Style: Corner Radius

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6127311 |

| ISO Catalog ID | FMDF2000X6CQF |

| ANSI Catalog ID | FMDF2000X6CQF |

| Grade | KCPM15 |

| Adapter Style Machine Side | DUO-LOCK |

| [D1] Effective Cutting Diameter | 20 mm |

| [D1] Effective Cutting Diameter | 0.7874 in |

| [D] Adapter / Shank / Bore Diameter | 19.3 mm |

| [D] Adapter / Shank / Bore Diameter | 0.7598 in |

| [AP1MAX] 1st Maximum Cutting Depth | 30 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.1811 in |

| [L1] Gage Length | 45 mm |

| [L1] Gage Length | 1.7717 in |

| [CSMS] System Size Machine Side | DL20 |

| [WF] Width of Flat | 16 mm |

| [WF] Width of Flat | 0.6299 in |

| [Re] Corner Radius | 0.75 mm |

| [Re] Corner Radius | 0.03 in |

| [Z] Number of Flutes | 6 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 6

Helix Angle: 45°

Corner Style: Corner Radius

Grades

KCPM15

Coated carbide grade with thick PVD coating and optimized chemistry and process for increased wear resistance. Outstanding protection in milling stainless steel to mitigate crater, DOCN (depth-of-cut notching), and flank wear. Excellent performance up to 52 HRC.

Features and benefits

- Modular end mill for high performance finishing in steels and stainless steels.

- Centre cutting.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

FMDF • Metric

| Material |  | short | medium | long | Recommended feed per tooth (fz = mm/th) for side milling (A). | |||||||||||||

| A | adapter reach | D1 | ||||||||||||||||

| KCPM15 | KCPM15 | KCPM15 | ||||||||||||||||

| Cutting Speed | Cutting Speed | Cutting Speed | ||||||||||||||||

| ap | ae | Min | Max | Min | Max | Min | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | |||||

| P | 0 | 1,5 x D | 0,1 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 |

| 1 | 1,5 x D | 0,1 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 | |

| 2 | 1,5 x D | 0,1 x D | 140 | – | 190 | 126 | – | 171 | 126 | – | 171 | fz | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 | |

| 3 | 1,5 x D | 0,1 x D | 120 | – | 160 | 108 | – | 144 | 108 | – | 144 | fz | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 | |

| 4 | 1,5 x D | 0,1 x D | 90 | – | 150 | 81 | – | 135 | 81 | – | 135 | fz | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 | |

| 5 | 1,5 x D | 0,1 x D | 60 | – | 100 | 51 | – | 85 | 48 | – | 80 | fz | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 6 | 1,5 x D | 0,1 x D | 50 | – | 75 | 42,5 | – | 63,75 | 40 | – | 60 | fz | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| M | 1 | 1,5 x D | 0,1 x D | 90 | – | 115 | 72 | – | 92 | 63 | – | 80,5 | fz | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1,5 x D | 0,1 x D | 60 | – | 80 | 48 | – | 64 | 42 | – | 56 | fz | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| 3 | 1,5 x D | 0,1 x D | 60 | – | 70 | 48 | – | 56 | 42 | – | 49 | fz | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

| K | 1 | 1,5 x D | 0,1 x D | 120 | – | 150 | 108 | – | 135 | 108 | – | 135 | fz | 0,072 | 0,083 | 0,101 | 0,114 | 0,124 |

| 2 | 1,5 x D | 0,1 x D | 110 | – | 140 | 99 | – | 126 | 99 | – | 126 | fz | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 | |

| 3 | 1,5 x D | 0,1 x D | 110 | – | 130 | 99 | – | 117 | 99 | – | 117 | fz | 0,048 | 0,056 | 0,070 | 0,081 | 0,091 | |

| S | 1 | 1,5 x D | 0,1 x D | 50 | – | 90 | 40 | – | 72 | 30 | – | 54 | fz | 0,061 | 0,070 | 0,087 | 0,101 | 0,114 |

| 2 | 1,5 x D | 0,1 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 3 | 1,5 x D | 0,1 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,032 | 0,037 | 0,046 | 0,054 | 0,061 | |

| 4 | 1,5 x D | 0,15 x D | 50 | – | 60 | 40 | – | 48 | 30 | – | 36 | fz | 0,045 | 0,052 | 0,064 | 0,074 | 0,084 | |

| H | 1 | 1,5 x D | 0,1 x D | 80 | – | 140 | 64 | – | 112 | 48 | – | 84 | fz | 0,054 | 0,062 | 0,077 | 0,088 | 0,098 |

| 2 | 1,5 x D | 0,1 x D | 70 | – | 120 | 56 | – | 96 | 42 | – | 72 | fz | 0,040 | 0,047 | 0,057 | 0,065 | 0,071 | |

Tolerance

| End Mill Tolerances | |

| D1 | tolerance e8 |

| -0,032/-0,059 | |

| -0,040/-0,073 | |

| -0,050/-0,089 | |

I have read and accepted the Terms & Conditions of use