Product Similar To:

Mill 1-10™ • Carbide Insert with PCD Tip • EDCT-PCD • High-Speed machining of Aluminum

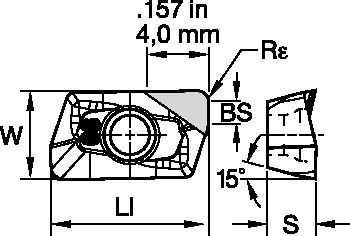

Shoulder milling insert with one cutting edge per insert

Material Number3759083

ISO Catalog IDEDCT10T304PDFR-PCDANSI Catalog IDEC1004FR-PCD

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3759083 |

| ISO Catalog ID | EDCT10T304PDFR-PCD |

| ANSI Catalog ID | EC1004FR-PCD |

| Grade | KD1410 |

| [LI] Insert Length | 12.01 mm |

| [LI] Insert Length | 0.4728 in |

| [S] Insert Thickness | 3.75 mm |

| [S] Insert Thickness | 0.148 in |

| [W] Insert Width | 6.75 mm |

| [W] Insert Width | 0.266 in |

| [BS] Corner Facet Length | 2.26 mm |

| [BS] Corner Facet Length | 0.089 in |

| [Rε] Corner Radius | 0.4 mm |

| [Rε] Corner Radius | 0.016 in |

| Average Chip Thickness [HM] | 0.02 mm |

| Average Chip Thickness [HM] | 0.0008 in |

| Cutting Edges per Insert | 1 |

Workpiece Materials

- Non-Ferrous

Grades

KD1410

A PCD-tip brazed to carbide for machining aluminum with a very high silicon content, abrasive non-ferrous materials, and fiber-reinforced plastics. KD1410 can be used at very high cutting speeds, even where good surface finishes are required. This grade can be used both wet or dry but is suggested to use coolant where good surface finishes are required.

Features and benefits

- For roughing and finishing of aluminum and non-ferrous materials

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| Material | Light | Medium | Heavy | |||

| P1–P2 | .E..LD | KCPM40 | .S..GD | KCPM40 | .E..HD | KCPM40 |

| P3–P4 | .E..LD | KCPK30 | .S..GD | KCPK30 | .E..HD | KCPK30 |

| P5–P6 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| M1–M2 | .E..LD | KCSM40 | .S..GD | KC725M | .E..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .S..GD | KCPM40 | .E..HD | KCSM40 |

| K1–K2 | .E..LD | KCK15 | .S..GD | KCK15 | .E..HD | KCK15 |

| K3 | .E..LD | KCK20B | .S..GD | KCK20B | .E..HD | KCK20B |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC422M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .E..LDJ | KC422M | .E..LDJ | KC422M |

| S1–S2 | .E..LD | KC725M | .S..GD | KC725M | .E..HD | KC725M |

| S3 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .S..GE | KCSM40 | .E..HD | KCSM40 |

| H1 | .E..LD | KC510M | – | – | – | – |

I have read and accepted the Terms & Conditions of use