환영합니다

기본 설정을 확인해 주십시오

기본 설정 업데이트

제품 제안

Product Family suggestions

솔루션 수정

솔루션 추가

솔루션 이름:{{SolutionName}}Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

MaxiMet™ • Square End • 2 Flutes • Wiper Facet • Necked • Plain Shank • Inch

MaxiMet™ Solid Carbide End Mill for Roughing and Finishing of Aluminum

특징 및 장점

- MaxiMet™ solid carbide end mills are very effective in thin wall applications.

- Centre cutting for plunging and ramping operations.

- Wiper facet, unique end gash, and unique flute geometry provide optimum surface finishes.

사용 및 응용 분야

램핑: 블랭크

슬로팅: 스퀘어 엔드

사이드 밀링/숄더 밀링: 스퀘어 엔드

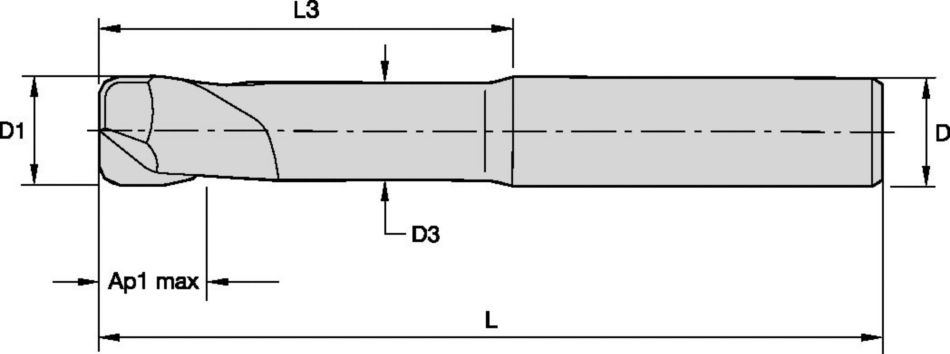

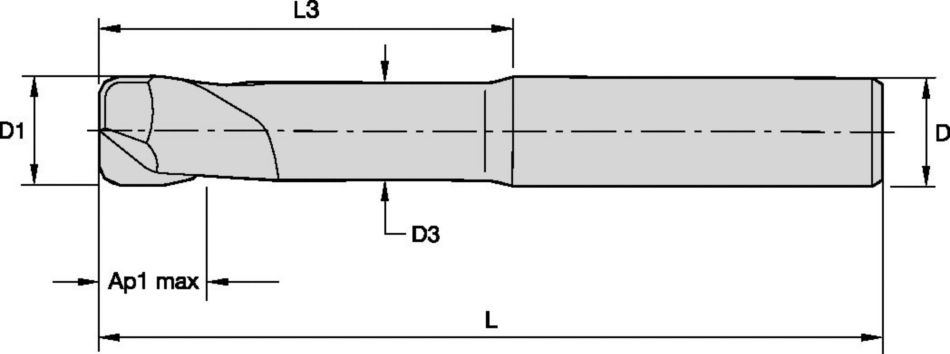

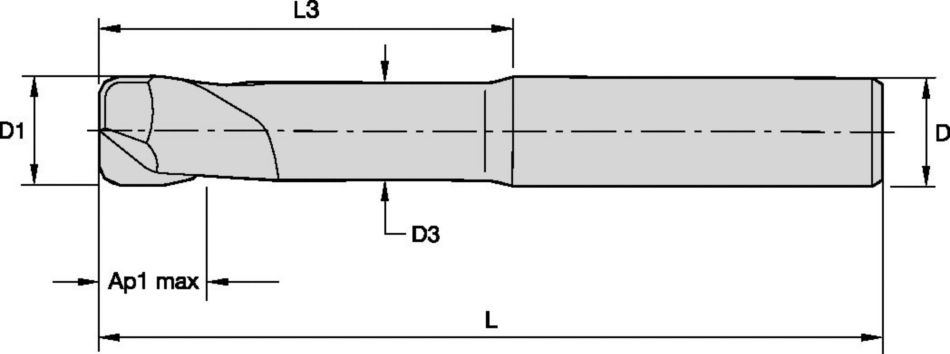

공구 치수: 플루트 구성: 2

헬릭스각: 45°

코너 스타일: 코너R

코너 스타일: 스퀘어 엔드

| Parmak freze toleransları | |||

| D1 | Tolerans h6 + / - | D | Tolerans h6 + / - |

| 1/8" | +0/-.002" | 1/8" | +0/-.00024" |

| 1/8 | +0/-.002" | 1/8 | +0/-.00031" |

| 1/4 | +0/-.00035" | 1/4 | +0/-.00035" |

| 13/32 | +0/-.00043" | 13/32 | +0/-.00043" |

| 23/32 | +0/-.00051" | 23/32 | +0/-.00051" |

| Malzeme grubu |  |  |  | |||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | K600 | Kenar frezeleme (A) için önerilen diş başına ilerleme (IPT = inç/diş). Kanal açma (B) için IPT %20 azaltılır. | ||||||||||||

| A | B | Kesme hızı | D1 | |||||||||||

| frac. | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | ap | min | max | dec. | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| N | 1 | 1 x D | 0.5 x D | 1.0 x D | 1640 | 6560 | IPT | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | 1 x D | 0.5 x D | 1.0 x D | 1640 | 4920 | IPT | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 3 | 1 x D | 0.5 x D | 1.0 x D | 1640 | 4920 | IPT | .0018 | .0022 | .0026 | .0035 | .0044 | .0053 | .0070 | |

| 4 | 1 x D | 0.5 x D | 1.0 x D | 1310 | 2460 | IPT | .0018 | .0022 | .0026 | .0035 | .0044 | .0053 | .0070 | |

| 5 | 1 x D | 0.5 x D | 1.0 x D | 820 | 3280 | IPT | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |

| Material |  |  |  | |||||||||||

| Side Milling (A) and Slotting (B) | K600 | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | ||||||||||||

| A | B | Cutting Speed | D1 | |||||||||||

| frac. | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | |||||||

| ap | ae | ap | min | max | dec. | .2500 | .3125 | .3750 | .5000 | .6250 | .7500 | 1.0000 | ||

| N | 1 | 1 x D | 0.5 x D | 1.0 x D | 1640 | 6560 | IPT | .0025 | .0031 | .0038 | .0050 | .0063 | .0075 | .0100 |

| 2 | 1 x D | 0.5 x D | 1.0 x D | 1640 | 4920 | IPT | .0020 | .0025 | .0030 | .0040 | .0050 | .0060 | .0080 | |

| 3 | 1 x D | 0.5 x D | 1.0 x D | 1640 | 4920 | IPT | .0018 | .0022 | .0026 | .0035 | .0044 | .0053 | .0070 | |

| 4 | 1 x D | 0.5 x D | 1.0 x D | 1310 | 2460 | IPT | .0018 | .0022 | .0026 | .0035 | .0044 | .0053 | .0070 | |

| 5 | 1 x D | 0.5 x D | 1.0 x D | 820 | 3280 | IPT | .0023 | .0028 | .0034 | .0045 | .0056 | .0068 | .0090 | |