Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Enter to Win a 1-Year FREE Subscription to Fusion Enter Today!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Indexable Milling

- /

- Face Mills

- /

- Dodeka Series

- /

- Dodeka™ Mini

- /

- Dodeka™ Mini Inserts

- /

- Dodeka™ Mini 45° • Wiper Carbide Insert • XNGJ-LD3W • Fine Finishing of Multiple Materials

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

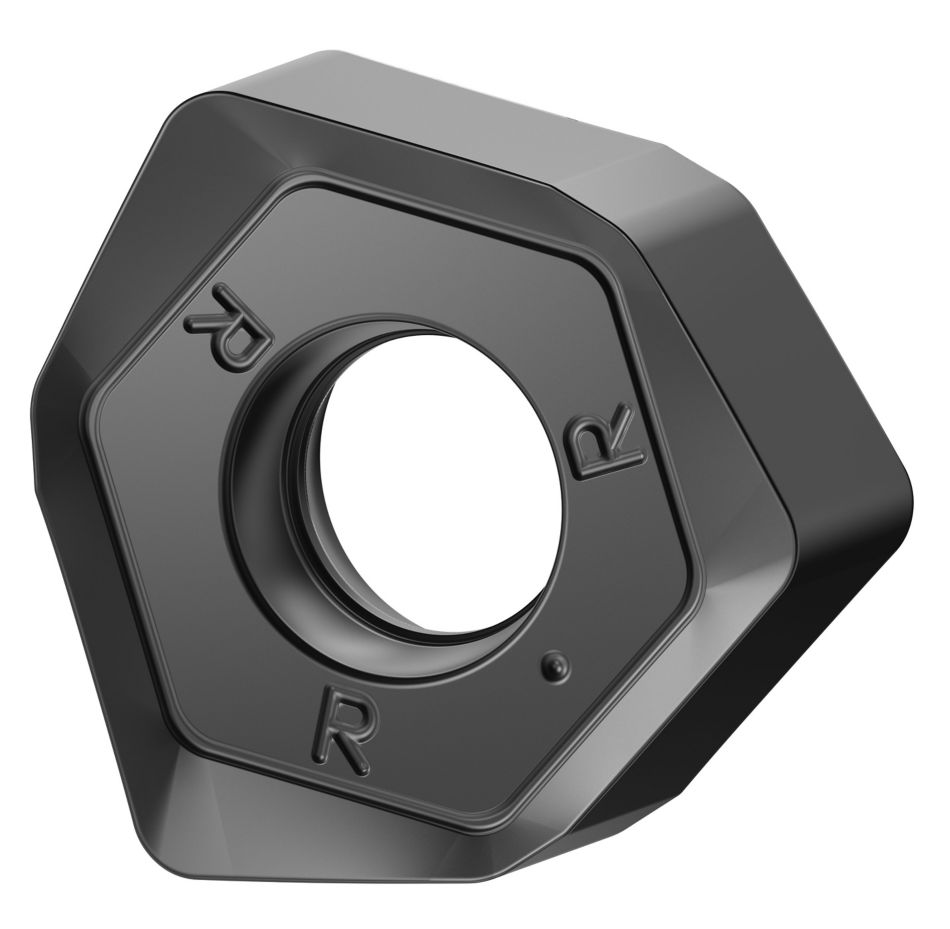

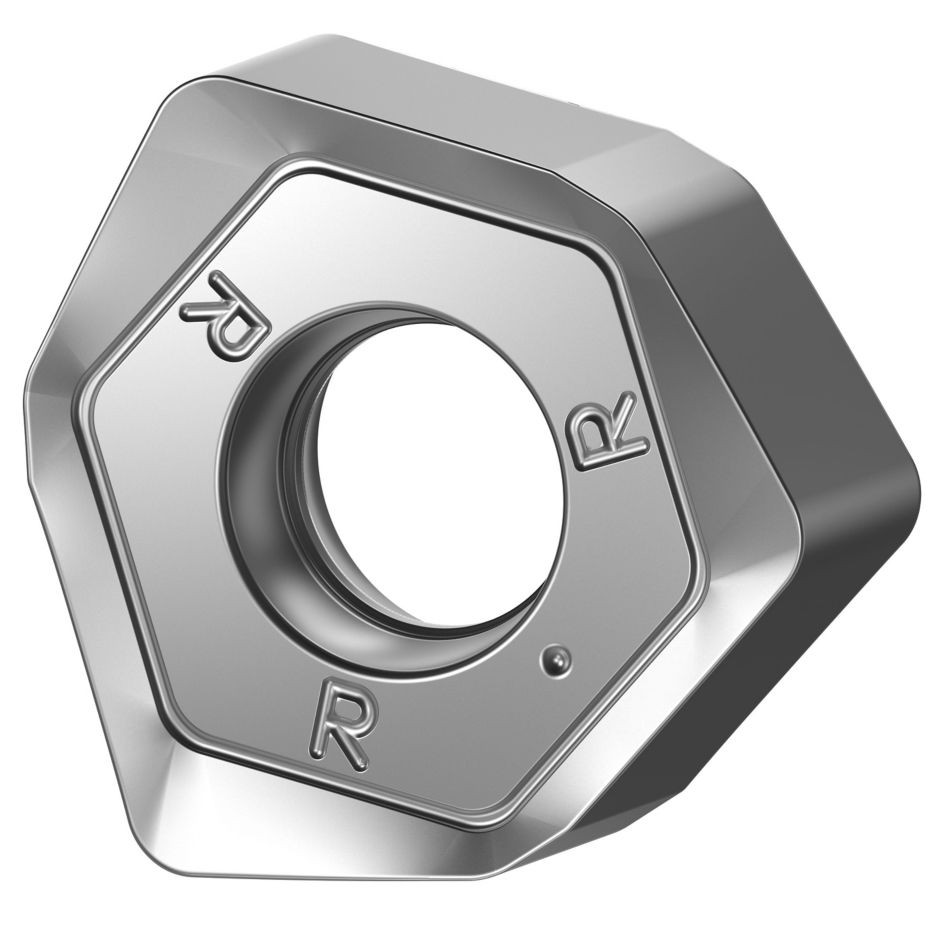

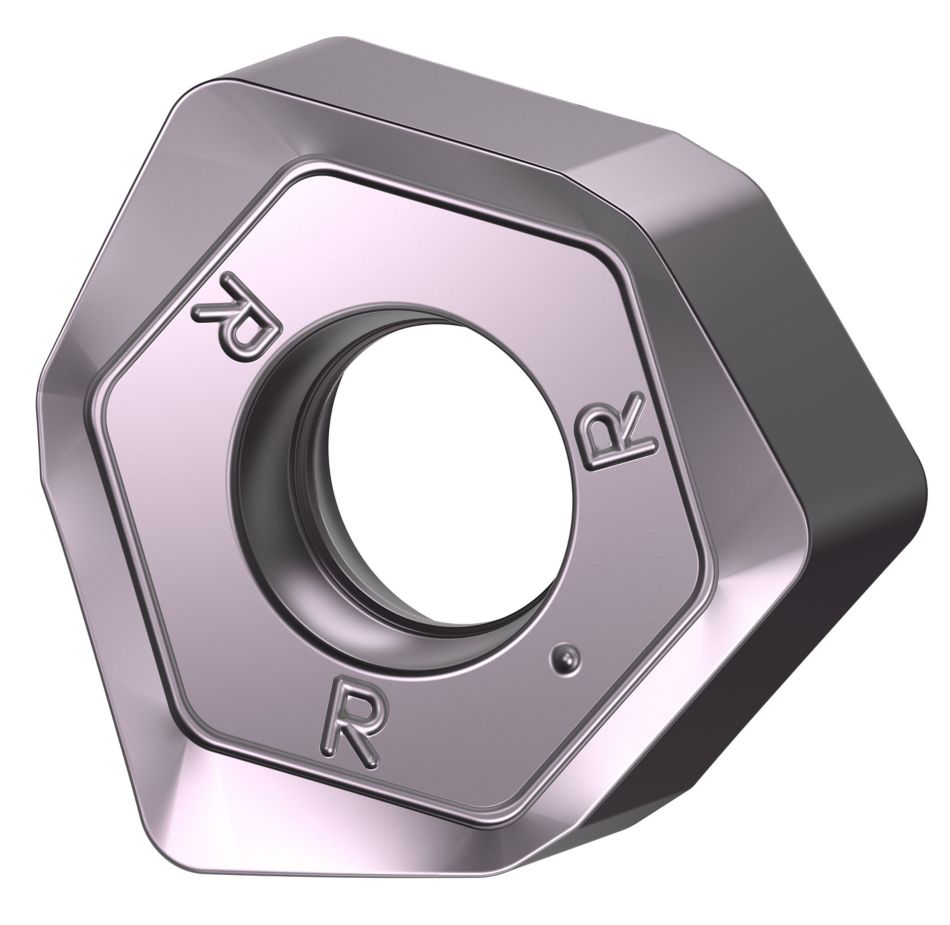

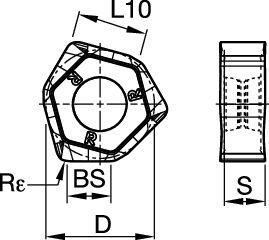

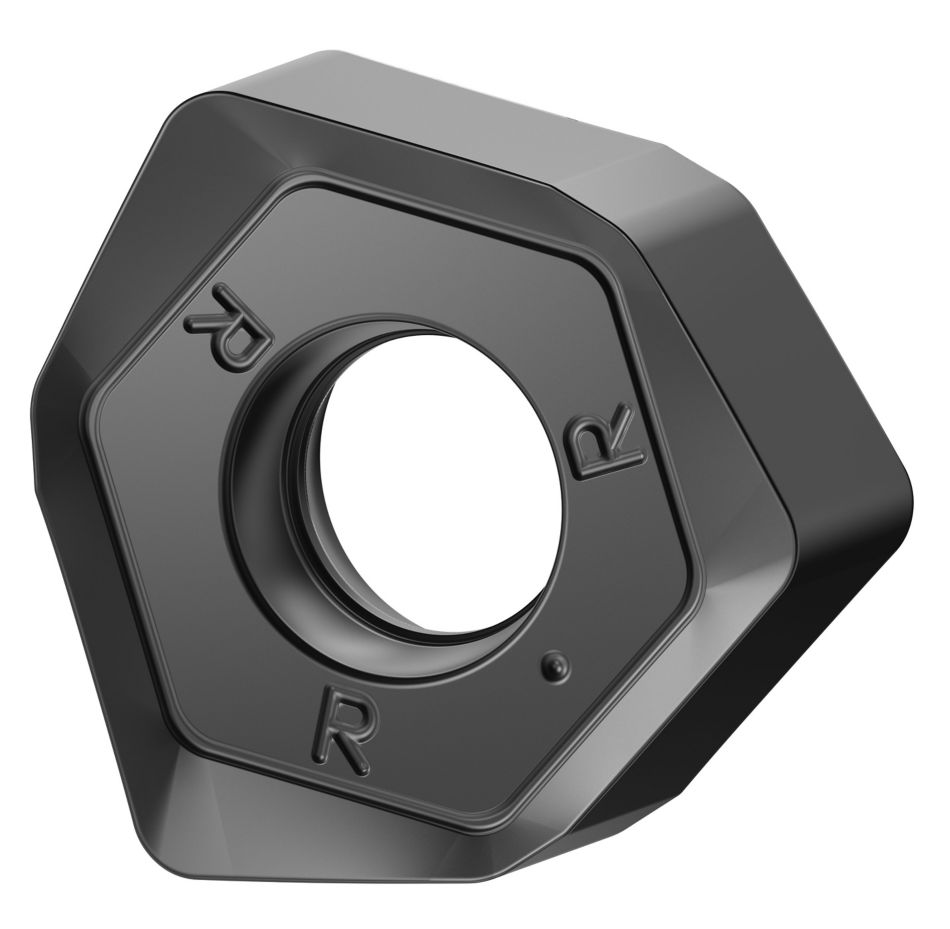

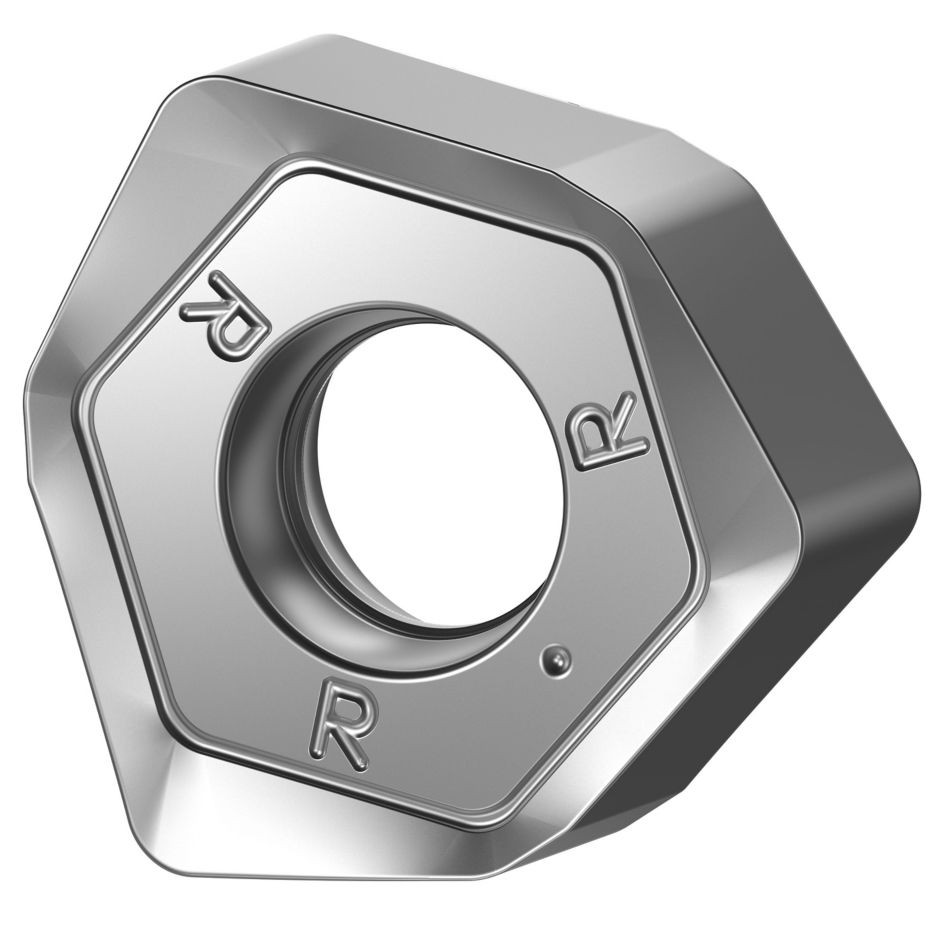

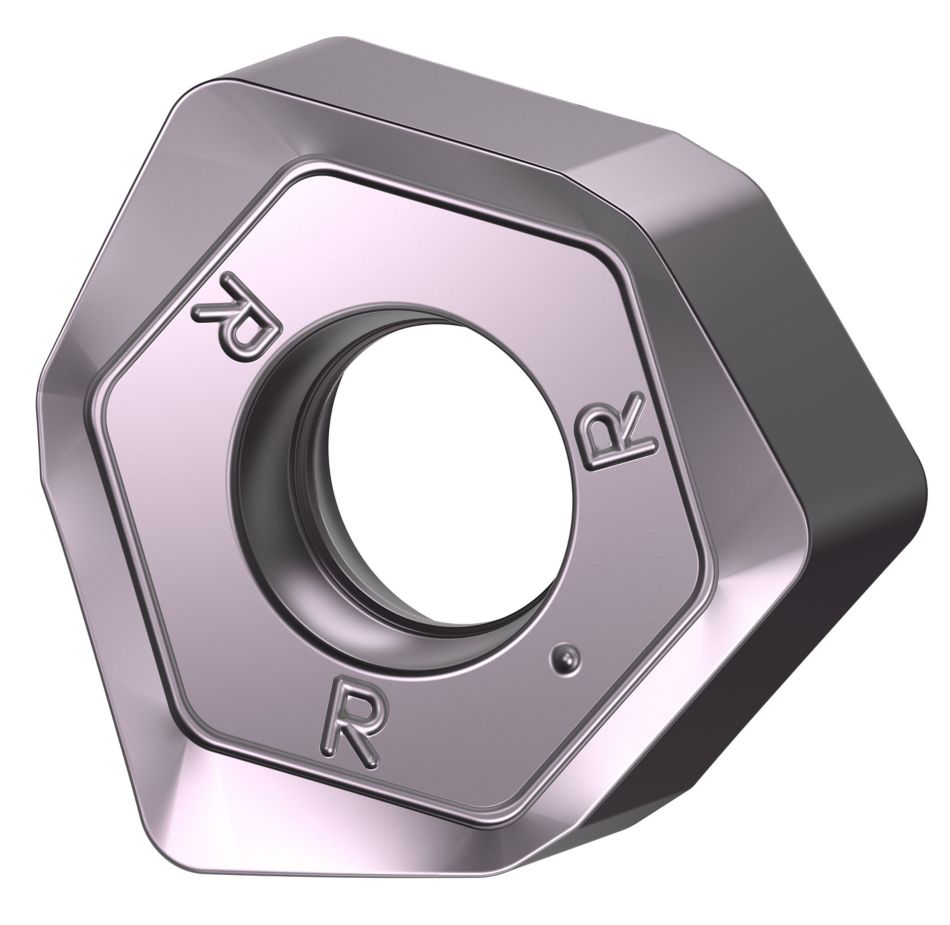

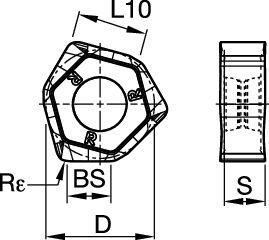

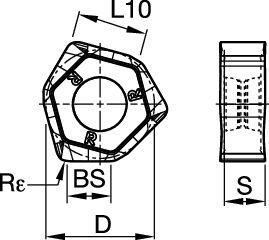

Dodeka™ Mini 45° • Wiper Carbide Insert • XNGJ-LD3W • Fine Finishing of Multiple Materials

Face milling wiper insert, precision ground.

Features and benefits

- Wiper insert for excellent floor finish.

| Material | Light | Medium | Heavy | |||||||

| P1–P2 | .E..LD | KC522M | .E..LP | KC522M | .E..GP | KC522M | .S..GD | KC522M | .S..HD | KC725M |

| P3–P4 | .E..LD | KCPM40 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPK30 | .S..HD | KCPK30 |

| P5–P6 | .E..LD | KCPM40 | .E..LP | KCPM40 | .E..GP | KCPM40 | .S..GD | KCPM40 | .S..HD | KCPM40 |

| M1–M2 | .E..LD | KC522M | .E..LM | KC522M | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| M3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCPM40 |

| K1–K2 | .E..LD | KCK20B | .E..LP | KCK20B | .E..LP | KCK20B | .S..GD | KCK15 | .S..HD | KCK15 |

| K3 | .E..LD | KCKP10 | .E..LP | KCPK30 | .E..LP | KCPK30 | .S..GD | KCK20B | .S..HD | KCPK30 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LD | KCKP10 |

| S1–S2 | .E..LD | KC725M | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KC725M | .S..HD | KC725M |

| S3 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| S4 | .E..LD | KCSM40 | .E..LM | KCSM40 | .E..GM | KCSM40 | .S..GD | KCSM40 | .S..HD | KCSM40 |

| H1 | .E..LD | KCKP10 | – | – | .E..GP | KC522M | – | – | – | – |