Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Sign Out

Item(s)

successfully added to cart

View Cart

View Cart

Spring into action with the latest deals on your favorite tools.

Shop Now!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Indexable Milling

- /

- Face Mills

- /

- KSSM 45°

- /

- Inserts for KSSM 45° • SEKT-GP2

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

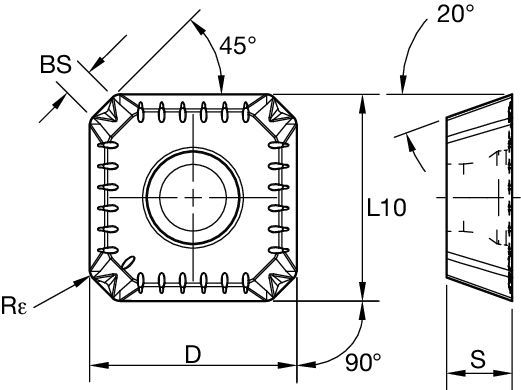

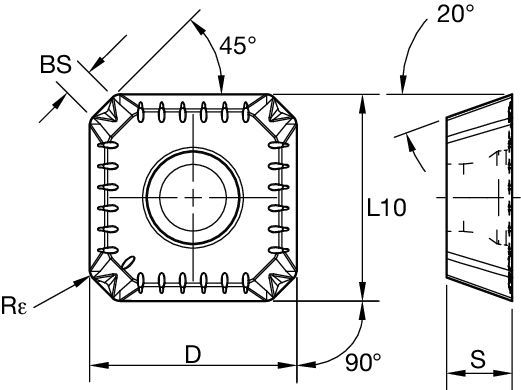

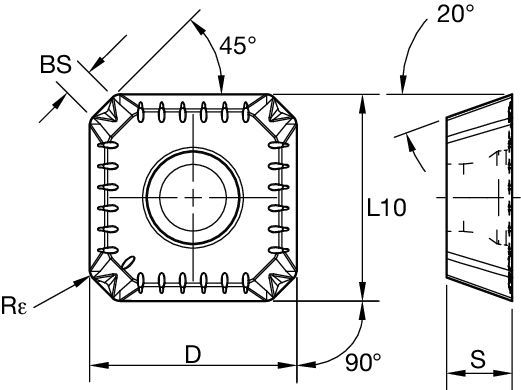

Inserts for KSSM 45° • SEKT-GP2

Indexable Inserts

Insert Selection Guide

| Material Group | Light

|

General

|

Heavy

|

|||

| (Light geometry) | – | (Strong geometry) | ||||

| wear

|

<="" td=""> <="" td=""> | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | .E..GP2 | KCPM40 | .E..GB2 | KCPM40 | .S..GB2 | KCPM40 |

| P3–P4 | .E..GP2 | KCPK30 | .E..GB2 | KCPK30 | .S..GB2 | KCPK30 |

| P5–P6 | .E..GP2 | KC725M | .E..GB2 | KC725M | .S..GB2 | KC725M |

| M1–M2 | .E..LD2 | KC725M | .E..GP2 | KC725M | .S..GP2 | KC725M |

| M3 | .E..GP2 | KCPM40 | .E..GB2 | KCPM40 | .S..GP2 | KCPM40 |

| K1–K2 | .E..GP2 | KCK15 | .E..GB2 | KCK15 | .S..GB2 | KCK15 |

| K3 | .E..GP2 | KC520M | .E..GB2 | KC520M | .S..GB2 | KC520M |

| N1–N2 | .F..LE | KC410M | .F..LE | KC410M | .F..LE | KC410M |

| N3 | .F..LE | KC410M | .F..LE | KC410M | .F..LE | KC410M |

| S1–S2 | .E..LD2 | KC725M | .E..GP2 | KC725M | .S..GP2 | KC725M |

| S3 | .E..GB2 | KC725M | .S..GP2 | KC725M | .S..GB2 | KC725M |

| S4 | .E..GB2 | KC725M | .S..GP2 | KC725M | .S..GB2 | KC725M |

| H1 | – | – | – | – | – | – |

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LE | 0,17 | 0,59 | 0,99 | 0,12 | 0,43 | 0,71 | 0,09 | 0,32 | 0,53 | 0,08 | 0,28 | 0,46 | 0,07 | 0,25 | 0,42 | .F..LE |

| .E..LD2 | 0,17 | 0,62 | 1,15 | 0,13 | 0,45 | 0,82 | 0,10 | 0,34 | 0,61 | 0,08 | 0,29 | 0,53 | 0,08 | 0,27 | 0,49 | .E..LD2 |

| .E..LD | 0,24 | 0,67 | 1,17 | 0,17 | 0,48 | 0,84 | 0,13 | 0,36 | 0,62 | 0,11 | 0,31 | 0,54 | 0,10 | 0,29 | 0,50 | .E..LD |

| .E..GP | 0,17 | 0,62 | 1,26 | 0,13 | 0,45 | 0,90 | 0,10 | 0,34 | 0,67 | 0,08 | 0,29 | 0,59 | 0,08 | 0,27 | 0,54 | .E..GP |

| .E..GP2 | 0,24 | 0,74 | 1,27 | 0,17 | 0,53 | 0,91 | 0,13 | 0,40 | 0,68 | 0,11 | 0,35 | 0,59 | 0,10 | 0,32 | 0,54 | .E..GP2 |

| .E..GB2 | 0,33 | 0,84 | 1,35 | 0,24 | 0,60 | 0,97 | 0,18 | 0,45 | 0,72 | 0,16 | 0,39 | 0,63 | 0,14 | 0,36 | 0,57 | .E..GB2 |

| .S..GP2 | 0,33 | 0,84 | 1,35 | 0,24 | 0,60 | 0,97 | 0,18 | 0,45 | 0,72 | 0,16 | 0,39 | 0,63 | 0,14 | 0,36 | 0,57 | .S..GP2 |

| .S..GB2 | 0,33 | 0,84 | 1,35 | 0,24 | 0,60 | 0,97 | 0,18 | 0,45 | 0,72 | 0,16 | 0,39 | 0,63 | 0,14 | 0,36 | 0,57 | .S..GB2 |

| .S..GN | 0,33 | 0,84 | 1,35 | 0,24 | 0,60 | 0,97 | 0,18 | 0,45 | 0,72 | 0,16 | 0,39 | 0,63 | 0,14 | 0,36 | 0,57 | .S..GN |

| Light

|

General

|

Heavy

|

Recommended Starting Feeds [IPT]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LE | .007 | .024 | .040 | .005 | .017 | .029 | .004 | .013 | .021 | .003 | .011 | .019 | .003 | .010 | .017 | .F..LE |

| .E..LD2 | .007 | .025 | .045 | .005 | .018 | .032 | .004 | .013 | .024 | .003 | .012 | .021 | .003 | .011 | .019 | .E..LD2 |

| .E..LD | .009 | .026 | .046 | .007 | .019 | .033 | .005 | .014 | .024 | .004 | .012 | .021 | .004 | .011 | .020 | .E..LD |

| .E..GP | .007 | .025 | .050 | .005 | .018 | .036 | .004 | .013 | .027 | .003 | .012 | .023 | .003 | .011 | .021 | .E..GP |

| .E..GP2 | .009 | .029 | .050 | .007 | .021 | .036 | .005 | .016 | .027 | .004 | .014 | .023 | .004 | .012 | .021 | .E..GP2 |

| .E..GB2 | .013 | .033 | .053 | .009 | .024 | .038 | .007 | .018 | .028 | .006 | .015 | .025 | .006 | .014 | .023 | .E..GB2 |

| .S..GP2 | .013 | .033 | .053 | .009 | .024 | .038 | .007 | .018 | .028 | .006 | .015 | .025 | .006 | .014 | .023 | .S..GP2 |

| .S..GB2 | .013 | .033 | .053 | .009 | .024 | .038 | .007 | .018 | .028 | .006 | .015 | .025 | .006 | .014 | .023 | .S..GB2 |

| .S..GN | .013 | .033 | .053 | .009 | .024 | .038 | .007 | .018 | .028 | .006 | .015 | .025 | .006 | .014 | .023 | .S..GN |

| Light

|

General

|

Heavy

|

Recommended Starting Speeds [m/min]

| Material Group | KC410M | KC520M | KC725M | KCK15 | KCPM20 | KCPK30 | KY3500 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 315 | 275 | 255 | – | – | – | 660 | 580 | 535 | 545 | 475 | 440 | – | – | – |

| 2 | – | – | – | – | – | – | 260 | 230 | 195 | – | – | – | 410 | 370 | 330 | 335 | 305 | 275 | – | – | – | |

| 3 | – | – | – | – | – | – | 240 | 205 | 170 | – | – | – | 370 | 330 | 305 | 305 | 275 | 250 | – | – | – | |

| 4 | – | – | – | – | – | – | 215 | 180 | 145 | – | – | – | 275 | 255 | 230 | 225 | 210 | 190 | – | – | – | |

| 5 | – | – | – | – | – | – | 180 | 160 | 145 | – | – | – | 330 | 300 | 275 | 310 | 275 | 255 | – | – | – | |

| 6 | – | – | – | – | – | – | 160 | 120 | 95 | – | – | – | 230 | 200 | 175 | 190 | 165 | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | 205 | 180 | 165 | – | – | – | 270 | 240 | 205 | 250 | 220 | 190 | – | – | – |

| 2 | – | – | – | – | – | – | 185 | 160 | 130 | – | – | – | 245 | 215 | 190 | 225 | 195 | 170 | – | – | – | |

| 3 | – | – | – | – | – | – | 140 | 120 | 95 | – | – | – | 195 | 175 | 150 | 175 | 160 | 140 | – | – | – | |

| K | 1 | – | – | – | 325 | 295 | 260 | – | – | – | 505 | 460 | 410 | 435 | 390 | 350 | 355 | 320 | 285 | 965 | 880 | 780 |

| 2 | – | – | – | 255 | 225 | 215 | – | – | – | 400 | 355 | 330 | 345 | 310 | 280 | 280 | 255 | 230 | 765 | 685 | 635 | |

| 3 | – | – | – | 215 | 190 | 170 | – | – | – | 335 | 300 | 275 | 290 | 255 | 240 | 235 | 210 | 195 | 645 | 570 | 525 | |

| N | 1–2 | 1460 | 1300 | 1195 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 1300 | 1195 | 1100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 45 | 35 | 30 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 45 | 35 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 55 | 45 | 30 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 75 | 55 | 35 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Material Group | KC410M | KC520M | KC725M | KCK15 | KCPM20 | KCPK30 | KY3500 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 1030 | 900 | 840 | – | – | – | 2170 | 1910 | 1760 | 1780 | 1560 | 1450 | – | – | – |

| 2 | – | – | – | – | – | – | 860 | 760 | 640 | – | – | – | 1340 | 1210 | 1090 | 1100 | 1000 | 900 | – | – | – | |

| 3 | – | – | – | – | – | – | 790 | 670 | 550 | – | – | – | 1210 | 1090 | 1000 | 1000 | 900 | 820 | – | – | – | |

| 4 | – | – | – | – | – | – | 710 | 590 | 470 | – | – | – | 910 | 840 | 760 | 740 | 690 | 620 | – | – | – | |

| 5 | – | – | – | – | – | – | 590 | 530 | 470 | – | – | – | 1090 | 980 | 900 | 1020 | 910 | 830 | – | – | – | |

| 6 | – | – | – | – | – | – | 520 | 400 | 310 | – | – | – | 760 | 660 | 570 | 620 | 540 | - | – | – | – | |

| M | 1 | – | – | – | – | – | – | 670 | 590 | 540 | – | – | – | 880 | 790 | 680 | 820 | 720 | 620 | – | – | – |

| 2 | – | – | – | – | – | – | 610 | 520 | 430 | – | – | – | 800 | 700 | 620 | 730 | 640 | 550 | – | – | – | |

| 3 | – | – | – | – | – | – | 460 | 400 | 310 | – | – | – | 640 | 570 | 490 | 570 | 520 | 460 | – | – | – | |

| K | 1 | – | – | – | 1060 | 960 | 850 | – | – | – | 1660 | 1510 | 1340 | 1420 | 1280 | 1150 | 1160 | 1050 | 940 | 3170 | 2880 | 2560 |

| 2 | – | – | – | 830 | 740 | 700 | – | – | – | 1310 | 1170 | 1090 | 1130 | 1010 | 920 | 920 | 830 | 760 | 2510 | 2240 | 2090 | |

| 3 | – | – | – | 700 | 620 | 560 | – | – | – | 1100 | 980 | 900 | 950 | 840 | 780 | 770 | 690 | 640 | 2110 | 1870 | 1720 | |

| N | 1–2 | 4790 | 4260 | 3920 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 4260 | 3920 | 3600 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 140 | 120 | 100 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 140 | 120 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 180 | 140 | 100 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 240 | 180 | 120 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |