Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Logout

Item(s)

successfully added to cart

View Cart

View Cart

Spring into action with the latest deals on your favorite tools.

Shop Now!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

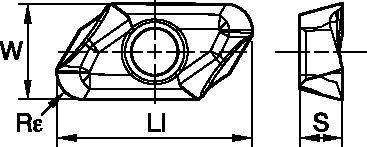

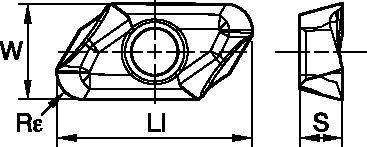

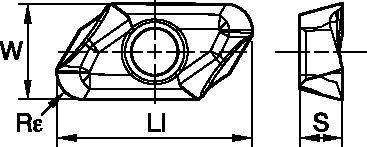

- ZDET16-ER721 • Stellram • Honed edge for roughing applications, apply under unstable and/or high rotation applications (≥24000 rpm spindle speed)

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

ZDET16-ER721 • Stellram • Honed edge for roughing applications, apply under unstable and/or high rotation applications (≥24000 rpm spindle speed)

Milling Inserts

Features and benefits

- Honed edge preparation for roughing applications. Apply under unstable conditions and/or high rotation applications.

| 5720 Series • Insert Selection Guide | ||||||

| Material Group | Light

|

General

|

Heavy

|

|||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear

|

<="" td=""> <="" td=""> | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | .F..721 | GH1 | .F..721 | GH1 | .F..721 | GH1 |

| N3 | .F..721 | GH1 | .F..721 | GH1 | .F..721 | GH1 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| 5720 Series • Recommended Starting Feeds [mm/th] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| ...FR721 | 0,12 | 0.45 | 0.81 | 0,08 | 0.33 | 0.58 | 0,06 | 0.25 | 0.43 | 0,06 | 0.21 | 0.38 | 0,05 | 0.2 | 0.35 |

| ...ER721 | 0.15 | 0.50 | 0.92 | 0.11 | 0.36 | 0.66 | 0.08 | 0.27 | 0.5 | 0.07 | 0,24 | 0.43 | 0.07 | 0,22 | 0,40 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||

| Light

|

General

|

Heavy

|

| size | Geometry | grade | operation | N | |

| Aluminium and Alloys 16% Si 116 HBN | Aluminium and Silicon

|

||||

| min–max | min–max | ||||

| 14mm | ...721 | GH1 | Profiling/Pocketing | 0,02

|

0,02

|

| Light

|

General

|

Heavy

|

| 5720 Series • Recommended Starting Feeds [IPT] | |||||||||||||||

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | |||||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | L | M | H | |

| ...FR721 | 0,12 | 0.45 | 0.81 | 0,08 | 0.33 | 0.58 | 0,06 | 0.25 | 0.43 | 0,06 | 0.21 | 0.38 | 0,05 | 0.2 | 0.35 |

| ...ER721 | 0.15 | 0.50 | 0.92 | 0.11 | 0.36 | 0.66 | 0.08 | 0.27 | 0.5 | 0.07 | 0,24 | 0.43 | 0.07 | 0,22 | 0,40 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | |||||||||||||||