Product Similar To :

Kenloc™ • DNMG Insert • Negative • RP

ISO Turning Carbide Insert • Roughing Positive Geometry

Material Number4050488

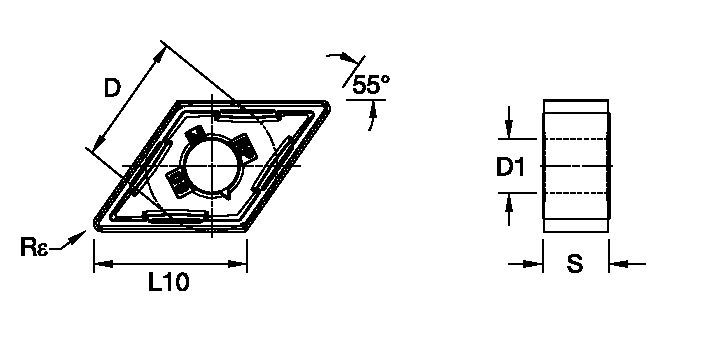

ISO Catalog IDDNMG150608RPANSI Catalog IDDNMG442RP

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4050488 |

| ISO Catalog ID | DNMG150608RP |

| ANSI Catalog ID | DNMG442RP |

| Grade | KCU25 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [L10] Insert Cutting Edge Length | 15.504 mm |

| [L10] Insert Cutting Edge Length | 0.6104 in |

| [S] Insert Thickness | 6.35 mm |

| [S] Insert Thickness | 0.25 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

| [D1] Insert Hole Size | 5.16 mm |

| [D1] Insert Hole Size | 0.2031 in |

Workpiece Materials

- High-Temp Alloys

Grades

KCU25

Composition: An advanced PVD grade with hard AlTiN coating and fine-grain unalloyed substrate. The new and improved coating improves edge stability with wide range speed and feed capabilities.

Application: The KCU25™ grade is ideal for general machining of most steels, stainless steels, high-temp alloys, titanium, irons, and non-ferrous materials in a wide range of speeds and feeds with improved edge toughness for interrupted cuts and high feed rates.

Features and benefits

- Roughing geometry with positive rake face for chip control in difficult materials

- Beyond™ Drive™ grades included

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use