Product Similar To:

Mill 1-14™ • Carbide Insert • EDPT-GE • Medium Machining

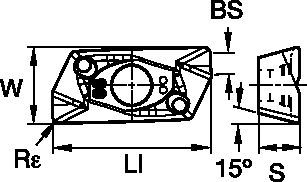

Shoulder milling insert with two cutting edges per insert

Material Number6172195

ISO Catalog IDEDPT140431PDSRGEANSI Catalog IDEP1431SGE

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6172195 |

| ISO Catalog ID | EDPT140431PDSRGE |

| ANSI Catalog ID | EP1431SGE |

| Grade | KCSM40 |

| [LI] Insert Length | 17.46 mm |

| [LI] Insert Length | .687 in |

| [S] Insert Thickness | 4.448 mm |

| [S] Insert Thickness | .1751 in |

| [W] Insert Width | 8.07 mm |

| [W] Insert Width | .318 in |

| [BS] Corner Facet Length | 0.13 mm |

| [BS] Corner Facet Length | .005 in |

| [Rε] Corner Radius | 3.1 mm |

| [Rε] Corner Radius | .122 in |

| Average Chip Thickness [HM] | 0.137 mm |

| Average Chip Thickness [HM] | .0054 in |

| Cutting Edges per Insert | 2 |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Features and benefits

- Pressed-to-size, for lowest cost per cutting edge.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| Material | Light | Medium | Heavy | |||

| P1–P2 | .E..GD | KCPM40 | .S..GD2 | KCPM40 | .E..HD2 | KCPM40 |

| P3–P4 | .E..GD | KCPM40 | .S..GD2 | KCPK30 | .E..HD2 | KCPK30 |

| P5–P6 | .E..GD | KC725M | .S..GD2 | KC725M | .E..HD2 | KC725M |

| M1–M2 | .E..LD | KC522M | .E..GD | KCSM40 | .E..HD2 | KC522M |

| M3 | .E..GD | KCSM40 | .S..GD2 | KCPM40 | .E..HD2 | KCPM40 |

| K1–K2 | .S..GD2 | KCK20B | .E..HD2 | KCK20B | .E..HD2 | KCK15 |

| K3 | .S..GD2 | KCK20B | .E..HD2 | KCK20B | .E..HD2 | KCK15 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LDJ | KC422M |

| S1–S2 | .E..GD | KC725M | .S..GD2 | KC725M | .E..HD2 | KC725M |

| S3 | .E..GD | KCSM40 | .S..GD2 | KC725M | .E..HD2 | KC725M |

| S4 | .E..GD | KCSM40 | .S..GD2 | KC725M | .E..HD2 | KC522M |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use