Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Sign Out

Item(s)

successfully added to cart

View Cart

View Cart

Enter to Win a 1-Year FREE Subscription to Fusion

Enter Today!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Solid Carbide End Milling

- /

- DUO-LOCK Modular Milling

- /

- DUO-LOCK Modular End Mills • Finishing

- /

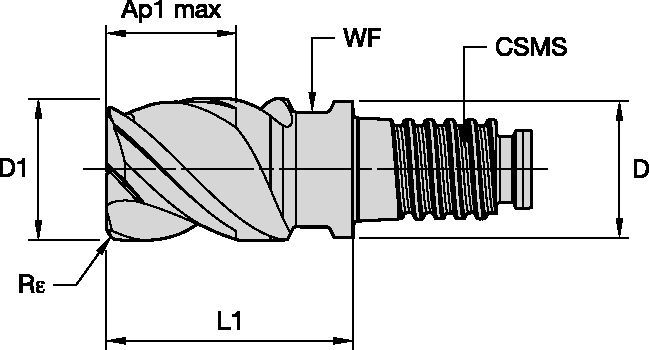

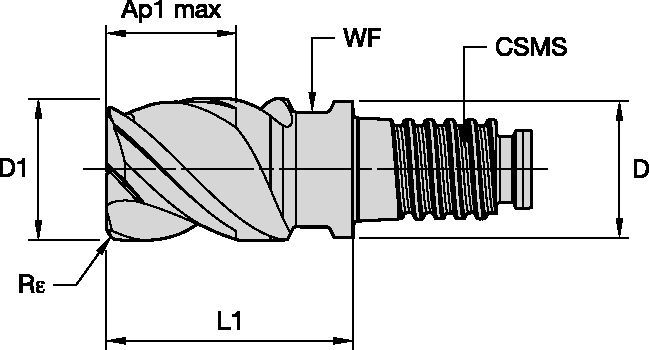

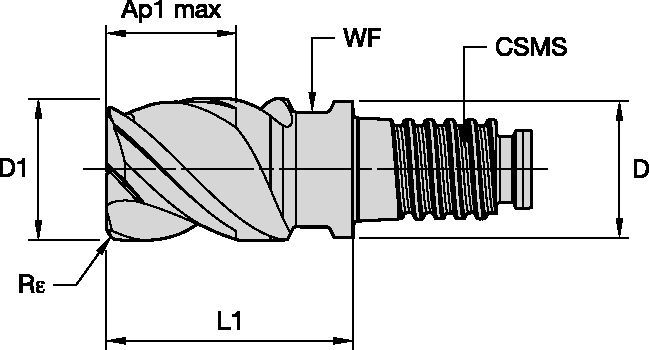

- DUO-LOCK™ • KenCut™ FF • Radiused • 3 Flutes • Metric

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

DUO-LOCK™ • KenCut™ FF • Radiused • 3 Flutes • Metric

Modular End Milling • FGDF Style • For MillTurn Machines and Lathes

Features and benefits

- Modular end mill for roughing and finishing in steels and stainless steel.

- Centre cutting.

- Short design and corner radii provide stability and reduce deflection forces.

- Ideally suited to perform long-reach applications on mill-turn machines, and driven tooling on lathes.

- The unique cutting geometry results in low cutting forces, resulting in low power consumption.

Uses and application

Helix Angle: 48°

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 3

Helix Angle: 42°

Helix Angle: 45°

Corner Style: Corner Radius

| End Mill Tolerances | |

| D1 | tolerance e8 |

|

|

-0,032/-0,059 |

|

|

-0,040/-0,073 |

|

|

-0,050/-0,089 |

DUO-LOCK™ • FGDF • 3 FLUTES • APPLICATION DATA

| Material

|

|

|

straight short | conical medium | conical long | Recommended feed per tooth (fz = mm/th) for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||||

| A | B | KCPM15 | KCPM15 | KCPM15 | D1

|

|||||||||||||

| Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

||||||||||||||||

| ap | ae | ap | Min | Max | Min | Max | Min | Max | mm | 10,0 | 12,0 | 16,0 | 20,0 | |||||

| P | 0 | 0,75 x D | 0,5 x D | 0,5 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,061 | 0,070 | 0,086 | 0,097 |

| 1 | 0,75 x D | 0,5 x D | 0,5 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,061 | 0,070 | 0,086 | 0,097 | |

| 2 | 0,75 x D | 0,5 x D | 0,5 x D | 140 | – | 190 | 126 | – | 171 | 126 | – | 171 | fz | 0,061 | 0,070 | 0,086 | 0,097 | |

| 3 | 0,75 x D | 0,4 x D | 0,5 x D | 120 | – | 160 | 108 | – | 144 | 108 | – | 144 | fz | 0,051 | 0,060 | 0,074 | 0,086 | |

| 4 | 0,75 x D | 0,3 x D | 0,5 x D | 90 | – | 150 | 81 | – | 135 | 81 | – | 135 | fz | 0,046 | 0,053 | 0,065 | 0,075 | |

| 5 | 0,75 x D | 0,4 x D | 0,5 x D | 60 | – | 100 | 51 | – | 85 | 48 | – | 80 | fz | 0,041 | 0,048 | 0,059 | 0,069 | |

| 6 | 0,75 x D | 0,3 x D | 0,5 x D | 50 | – | 75 | 43 | – | 64 | 40 | – | 60 | fz | 0,034 | 0,040 | 0,048 | 0,055 | |

| M | 1 | 0,75 x D | 0,4 x D | 0,5 x D | 90 | – | 115 | 72 | – | 92 | 63 | – | 81 | fz | 0,051 | 0,060 | 0,074 | 0,086 |

| 2 | 0,75 x D | 0,4 x D | 0,5 x D | 60 | – | 80 | 48 | – | 64 | 42 | – | 56 | fz | 0,041 | 0,048 | 0,059 | 0,069 | |

| 3 | 0,75 x D | 0,4 x D | 0,5 x D | 60 | – | 70 | 48 | – | 56 | 42 | – | 49 | fz | 0,034 | 0,040 | 0,048 | 0,055 | |

| K | 1 | 0,75 x D | 0,5 x D | 0,5 x D | 120 | – | 150 | 108 | – | 135 | 108 | – | 135 | fz | 0,061 | 0,070 | 0,086 | 0,097 |

| 2 | 0,75 x D | 0,5 x D | 0,5 x D | 110 | – | 140 | 99 | – | 126 | 99 | – | 126 | fz | 0,051 | 0,060 | 0,074 | 0,086 | |

| 3 | 0,75 x D | 0,4 x D | 0,5 x D | 110 | – | 130 | 99 | – | 117 | 99 | – | 117 | fz | 0,041 | 0,048 | 0,059 | 0,069 | |

| S | 1 | 0,3 x D | 0,3 x D | 0,5 x D | 50 | – | 90 | 40 | – | 72 | 30 | – | 54 | fz | 0,051 | 0,060 | 0,074 | 0,086 |

| 2 | 0,3 x D | 0,3 x D | 0,5 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,027 | 0,032 | 0,039 | 0,046 | |

| 3 | 0,75 x D | 0,3 x D | 0,5 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,027 | 0,032 | 0,039 | 0,046 | |

| 4 | 0,75 x D | 0,3 x D | 0,5 x D | 50 | – | 60 | 40 | – | 48 | 30 | – | 36 | fz | 0,038 | 0,044 | 0,055 | 0,063 | |

| H | 1 | 0,75 x D | 0,2 x D | 0,3 x D | 80 | – | 140 | 64 | – | 112 | 48 | – | 84 | fz | 0,046 | 0,053 | 0,065 | 0,075 |