Product Similar To:

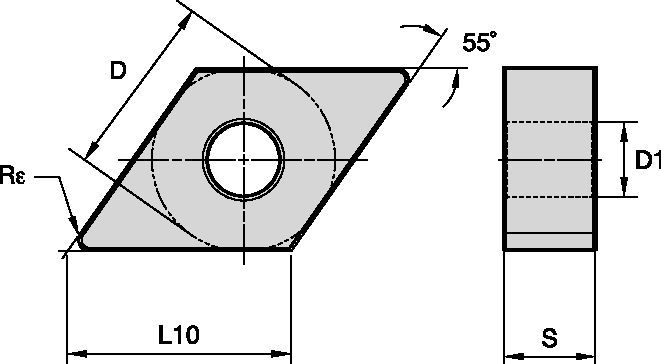

Kenloc™ • Negative Inserts • DNGA

ISO Turning Insert • Negative D-Style

Material Number1729944

ISO Catalog IDDNGA150612T01020ANSI Catalog IDDNGA443T0420

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1729944 |

| ISO Catalog ID | DNGA150612T01020 |

| ANSI Catalog ID | DNGA443T0420 |

| Grade | KY4400 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [L10] Insert Cutting Edge Length | 15.504 mm |

| [L10] Insert Cutting Edge Length | 0.6104 in |

| [S] Insert Thickness | 6.35 mm |

| [S] Insert Thickness | 0.25 in |

| [Rε] Corner Radius | 1.2 mm |

| [Rε] Corner Radius | 0.047 in |

Workpiece Materials

- Hardened Materials

Grades

KY4400

Composition: A PVD TiN coating over an aluminium oxide and titanium carbonitride composite ceramic (Al2O3/TiCN).

Application: Used for finish turning of hardened steels and irons (greater than 45 HRC). Where possible, use under dry conditions in smooth or varied depths of cut. Can also be applied in finish turning of nickel alloys, cobalt alloys, and powder metals.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use