Product Similar To:

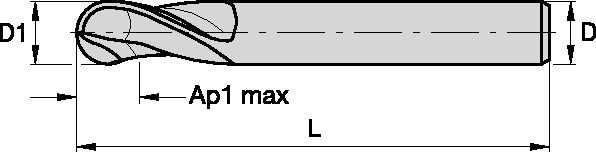

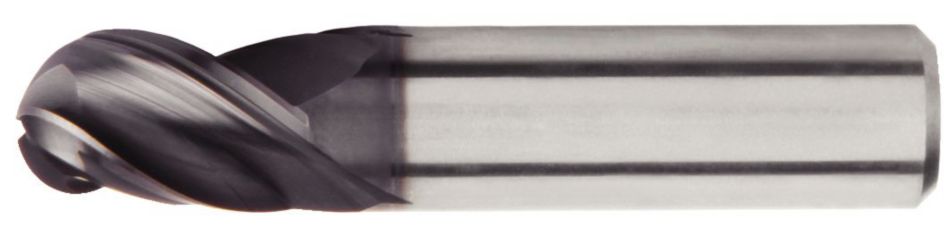

GOmill™ • Ball Nose • 3 Flutes • Plain Shank • Inch

Solid Carbide End Mill for Roughing and Finishing of Multiple Materials

Material Number4169835

ISO Catalog IDUEBD0250J3AANSI Catalog IDUEBD0250J3A

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Plunge Milling

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Tool Dimensions: Flute Configuration: 3

Helix Angle: 38°

Corner Style: Ball Nose

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4169835 |

| ISO Catalog ID | UEBD0250J3A |

| ANSI Catalog ID | UEBD0250J3A |

| Grade | KC643M |

| Adapter Style Machine Side | Straight-Cylindrical |

| [Z] Number of Flutes | 3 |

| [D1] Effective Cutting Diameter | 6.35 mm |

| [D1] Effective Cutting Diameter | .25 in |

| [D] Adapter / Shank / Bore Diameter | 6.35 mm |

| [D] Adapter / Shank / Bore Diameter | .25 in |

| [AP1MAX] 1st Maximum Cutting Depth | 8.33 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .3281 in |

| [L] Overall Length | 38.1 mm |

| [L] Overall Length | 1.5 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Plunge Milling

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Tool Dimensions: Flute Configuration: 3

Helix Angle: 38°

Corner Style: Ball Nose

Features and benefits

- Economic solid carbide end mill with short style shanks, saving expensive carbide.

- Not recommended for reconditioning.

- Extremely stable cutting conditions due to short design.

- Center cutting for plunging and ramping operations.

- Unequal flute spacing for chatter-free machining at highest feed rates.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| Parmak freze toleransları | |||

| D1 | Tolerans | D | Tolerans h6 + / - |

| Tümü | +.000/- .002" | ≤1/8" | +0/-.00024" |

| +0/-.00031" | |||

| +0/-.00035" | |||

| +0/-.00043" | |||

| +0/-.00051" | |||

Speeds & Feeds

|  |  | ||||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | ||||||||||||||

| KC643M | Recommended feed per tooth (IPT = inch/th) for side milling (A). For slotting (B), reduce IPT by 20%. | |||||||||||||

| A | B | Kesme hızı | D1 | |||||||||||

| inch | 5/64 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | |||||||

| Malzeme grubu | ap | ae | ap | min | max | 0.08 | 0.13 | 0.19 | 0.25 | 0.31 | 0.38 | 0.50 | ||

| P | 0 | 1.5 x D | 0.5 x D | 1 x D | 490 | 660 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 |

| 1 | 1.5 x D | 0.5 x D | 1 x D | 490 | 660 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 460 | 620 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 390 | 520 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | |

| 4 | 1.5 x D | 0.5 x D | 0.75 x D | 300 | 490 | IPT | .0004 | .0007 | .0010 | .0014 | .0017 | .0020 | .0026 | |

| 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | 330 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | 250 | IPT | .0003 | .0005 | .0008 | .0010 | .0013 | .0015 | .0019 | |

| M | 1 | 1.5 x D | 0.5 x D | 1 x D | 300 | 380 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 200 | 260 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | 230 | IPT | .0003 | .0005 | .0008 | .0010 | .0013 | .0015 | .0019 | |

| K | 1 | 1.5 x D | 0.5 x D | 1 x D | 390 | 490 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 360 | 460 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 360 | 430 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | 300 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | 130 | IPT | .0002 | .0004 | .0006 | .0008 | .0010 | .0012 | .0015 | |

| 3 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | 130 | IPT | .0002 | .0004 | .0006 | .0008 | .0010 | .0012 | .0015 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | 200 | IPT | .0003 | .0005 | .0008 | .0011 | .0014 | .0017 | .0021 | |

| H | 1 | 1.5 x D | 0.5 x D | 0.75 x D | 260 | 460 | IPT | .0004 | .0007 | .0010 | .0014 | .0017 | .0020 | .0026 |

|  |  | ||||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | KC643M | Kenar frezeleme (A) için önerilen diş başına ilerleme (IPT = inç/diş). Kanal açma (B) için IPT %20 azaltılır. | ||||||||||||

| A | B | Kesme hızı | D1 | |||||||||||

| inch | 5/64 | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | |||||||

| Malzeme grubu | ap | ae | ap | Min. | max | 0.08 | 0.13 | 0.19 | 0.25 | 0.31 | 0.38 | 0.50 | ||

| P | 0 | 1.5 x D | 0.5 x D | 1 x D | 490 | 660 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 |

| 1 | 1.5 x D | 0.5 x D | 1 x D | 490 | 660 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 460 | 620 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 390 | 520 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | |

| 4 | 1.5 x D | 0.5 x D | 0.75 x D | 300 | 490 | IPT | .0004 | .0007 | .0010 | .0014 | .0017 | .0020 | .0026 | |

| 5 | 1.5 x D | 0.5 x D | 1 x D | 200 | 330 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | |

| 6 | 1.5 x D | 0.5 x D | 0.75 x D | 160 | 250 | IPT | .0003 | .0005 | .0008 | .0010 | .0013 | .0015 | .0019 | |

| M | 1 | 1.5 x D | 0.5 x D | 1 x D | 300 | 380 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 200 | 260 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 200 | 230 | IPT | .0003 | .0005 | .0008 | .0010 | .0013 | .0015 | .0019 | |

| K | 1 | 1.5 x D | 0.5 x D | 1 x D | 390 | 490 | IPT | .0005 | .0009 | .0013 | .0018 | .0023 | .0027 | .0034 |

| 2 | 1.5 x D | 0.5 x D | 1 x D | 360 | 460 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 | |

| 3 | 1.5 x D | 0.5 x D | 1 x D | 360 | 430 | IPT | .0004 | .0006 | .0009 | .0012 | .0016 | .0018 | .0023 | |

| S | 1 | 1.5 x D | 0.3 x D | 0.3 x D | 160 | 300 | IPT | .0004 | .0007 | .0011 | .0015 | .0020 | .0023 | .0029 |

| 2 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | 130 | IPT | .0002 | .0004 | .0006 | .0008 | .0010 | .0012 | .0015 | |

| 3 | 1.5 x D | 0.3 x D | 0.3 x D | 80 | 130 | IPT | .0002 | .0004 | .0006 | .0008 | .0010 | .0012 | .0015 | |

| 4 | 1.5 x D | 0.5 x D | 1 x D | 160 | 200 | IPT | .0003 | .0005 | .0008 | .0011 | .0014 | .0017 | .0021 | |

| H | 1 | 1.5 x D | 0.5 x D | 0.75 x D | 260 | 460 | IPT | .0004 | .0007 | .0010 | .0014 | .0017 | .0020 | .0026 |

I have read and accepted the Terms & Conditions of use