Product Similar To:

HARVI™ I TE • Radiused • 4 Flutes • Plain Shank • Inch

HARVI™ I TE Four Flute End Mill for Roughing and Finishing Covering the Broadest Range of Applications and Materials

Material Number6676433

ISO Catalog IDH1TE4RA0625S075HAR060ANSI Catalog IDH1TE4RA0625S075HAR060

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Eased Chamfer

Tool Dimensions: Flute Configuration: 4

Shank - Cylindrical Plain

Pocketing

Side Milling/Shoulder Milling: Roughing

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6676433 |

| ISO Catalog ID | H1TE4RA0625S075HAR060 |

| ANSI Catalog ID | H1TE4RA0625S075HAR060 |

| Grade | KCSM15 |

| Adapter Style Machine Side | Straight-Cylindrical |

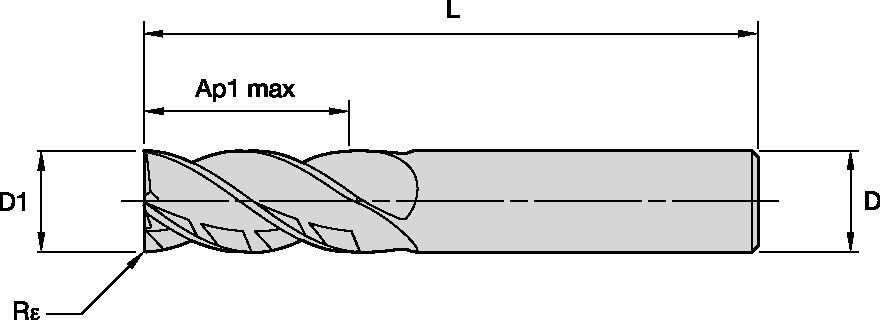

| [AP1MAX] 1st Maximum Cutting Depth | 19.05 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .75 in |

| [L] Overall Length | 76.2 mm |

| [L] Overall Length | 3 in |

| [Re] Corner Radius | 1.524 mm |

| [Re] Corner Radius | .06 in |

| [Z] Number of Flutes | 4 |

| [D1] Effective Cutting Diameter | 15.875 mm |

| [D1] Effective Cutting Diameter | .625 in |

| [D] Adapter / Shank / Bore Diameter | 15.875 mm |

| [D] Adapter / Shank / Bore Diameter | .625 in |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Uses and application

Trochoidal Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Square End

Side Milling/Shoulder Milling: Eased Chamfer

Tool Dimensions: Flute Configuration: 4

Shank - Cylindrical Plain

Pocketing

Side Milling/Shoulder Milling: Roughing

Features and benefits

- Versatile solid carbide end mill for steels, stainless steel, cast iron, and high temperature alloys.

- HARVI™ I TE solid carbide end mills cover a variety of operations, including dynamic milling, and extreme ramping operations.

- HARVI™ I TE solid carbide end mills stand for maximum metal removal, maximum productivity, maximum benefit.

- HARVI™ I TE solid carbide end mills feature asymmetrical divided flutes, variable helix, twisted end face, faceted eccentric relief, and chip gashes within the flutes.

- Centre cutting for plunging and ramping operations.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

TechnicalInfo

Adjustment Factor for Feed and Speed Calculation • Inch

| Ae/D | %2 | %4 | %5 | %8 | %10 | %12 | %20 | %30 | %40 | %50 | %100 | |

| Hız faktörü | Kv | 2,1 | 1,6 | 1,6 | 1,6 | 1,4 | 1,38 | 1,3 | 1,2 | 1,1 | 1 | 0,9 |

| İlerleme faktörü | KFz | 3,58 | 2,56 | 2,3 | 1,84 | 1,67 | 1,54 | 1,25 | 1,09 | 1,02 | 1 | 1 |

Application Data

HARVI™ I TE • 4 Flutes • Application Data • Inch

|  |  | ||||||||||||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | Kenar frezeleme (A) için önerilen diş başına ilerleme (IPT = inç/diş). Kanal açma (B) için IPT %20 azaltılır. | |||||||||||||||||||||

| KCPM15 | D1 | |||||||||||||||||||||

| A | B | Kesme hızı | frac. | 1/8 | 5/32 | 3/16 | 7/32 | 1/4 | 9/32 | 5/16 | 3/8 | 7/16 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||

| Malzeme grubu | ap | ae | ap | Min. | Maks. | dec. | .1250 | .1563 | .1875 | .2188 | .2500 | .2813 | .3125 | .3750 | .4375 | .5000 | .6250 | .7500 | 1.0000 | 1.2500 | ||

| P | 0 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | – | 660 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 |

| 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 490 | – | 660 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 | |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 460 | – | 620 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 390 | – | 520 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | – | 490 | IPT | .0007 | .0009 | .0011 | .0013 | .0015 | .0017 | .0019 | .0022 | .0025 | .0028 | .0033 | .0037 | .0042 | .0044 | |

| 5 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | – | 330 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| 6 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | – | 250 | IPT | .0006 | .0007 | .0008 | .0010 | .0011 | .0013 | .0014 | .0017 | .0019 | .0021 | .0025 | .0027 | .0031 | .0032 | |

| M | 1 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 300 | – | 380 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 200 | – | 260 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 200 | – | 230 | IPT | .0006 | .0007 | .0008 | .0010 | .0011 | .0013 | .0014 | .0017 | .0019 | .0021 | .0025 | .0027 | .0031 | .0032 | |

| K | 1 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 390 | – | 490 | IPT | .0010 | .0012 | .0015 | .0017 | .0020 | .0023 | .0026 | .0030 | .0034 | .0037 | .0043 | .0048 | .0054 | .0054 |

| 2 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | – | 460 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 360 | – | 430 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| S | 1 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | – | 300 | IPT | .0008 | .0010 | .0012 | .0014 | .0017 | .0019 | .0021 | .0025 | .0029 | .0032 | .0038 | .0042 | .0050 | .0053 |

| 2 | 1.5 x D1 | 0.3 x D1 | 0.75 x D1 | 160 | – | 260 | IPT | .0007 | .0008 | .0010 | .0012 | .0014 | .0015 | .0017 | .0020 | .0023 | .0025 | .0030 | .0034 | .0040 | .0043 | |

| 3 | 1.5 x D1 | 0.5 x D1 | 0.50 x D1 | 80 | – | 130 | IPT | .0004 | .0005 | .0007 | .0008 | .0009 | .0010 | .0011 | .0013 | .0015 | .0017 | .0020 | .0023 | .0027 | .0029 | |

| 4 | 1.5 x D1 | 0.5 x D1 | 1.25 x D1 | 160 | – | 200 | IPT | .0005 | .0007 | .0008 | .0010 | .0012 | .0014 | .0016 | .0019 | .0021 | .0023 | .0028 | .0031 | .0036 | .0039 | |

| H | 1 | 1.5 x D1 | 0.5 x D1 | 1.00 x D1 | 260 | – | 460 | IPT | .0007 | .0009 | .0011 | .0013 | .0015 | .0017 | .0019 | .0022 | .0025 | .0028 | .0033 | .0037 | .0042 | .0044 |

| 2 | 1.5 x D1 | 0.2 x D1 | 1.00 x D1 | 230 | – | 390 | IPT | .0006 | .0007 | .0008 | .0010 | .0011 | .0013 | .0014 | .0017 | .0019 | .0021 | .0025 | .0027 | .0031 | .0032 | |

I have read and accepted the Terms & Conditions of use