Product Similar To:

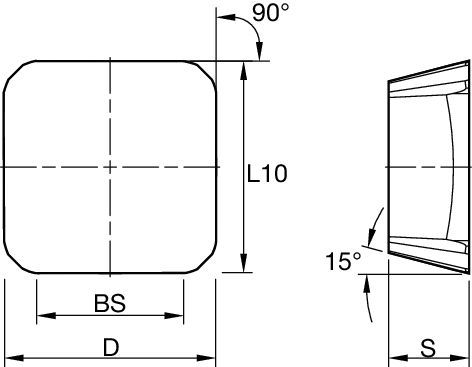

KCFM™ 45 • Carbide Wiper Insert • SDHN • Finishing

Milling insert with wiper facet • Honed T-Land

Material Number6210839

ISO Catalog IDSDHN1204ZZEN4WANSI Catalog IDSDHN43ZZEN4W

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6210839 |

| ISO Catalog ID | SDHN1204ZZEN4W |

| ANSI Catalog ID | SDHN43ZZEN4W |

| Grade | KC514M |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | .5 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | .187 in |

| [L10] Insert Cutting Edge Length | 12.7 mm |

| [L10] Insert Cutting Edge Length | .5 in |

| [BS] Corner Facet Length | 8.7 mm |

| [BS] Corner Facet Length | .3425 in |

| Average Chip Thickness [HM] | 0.08 mm |

| Average Chip Thickness [HM] | .003 in |

| Cutting Edges per Insert | 4 |

Features and benefits

- Milling insert for cast iron and compacted graphite iron (CGI) machining.

- Indexabe milling insert with four cutting edges.

- Carbide inserts are ideal for machines with lower spindle capabilities.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| – | Fine Finishing | Semi-Finishing | ||

| Material Group | Option 1: CBN | Option 2: Coated Carbide | Option 1: Advanced Material | Option 2: Coated Carbide |

| K1 | .S..R KBK50 | .E..R KC514M | .S..R KY3500/KBK50 | .E..R KC514M |

| K3 | – | .E..R KC514M | – | .E..R KC514M |

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| -SR | 0,06 | 0,12 | -SR | |||||||||||||

| -ER | 0,10 | 0,18 | -ER | |||||||||||||

| Fine Finishing | Semi-Finishing | Roughing |

Speeds

| Material Group | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 950 | 625 | 445 | 3935 | 2625 | 1970 | 3165 | 2870 | 2560 |

| 2 | 740 | 525 | 375 | 3935 | 2625 | 1970 | 2495 | 2245 | 2085 | |

| 3 | 625 | 445 | 360 | 3935 | 2625 | 1970 | 2100 | 1870 | 1705 | |

| Material Group | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 760 | 500 | 355 | – | – | – | – | – | – |

| 2 | 590 | 420 | 300 | – | – | – | – | – | – | |

| 3 | 500 | 355 | 290 | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use