Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account

Change Account

Ship To Account

Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

-

Notifications

Mark all as read - Change Password

- My Profile

- Sign Out

Item(s)

successfully added to cart

View Cart

View Cart

Enter to Win a 1-Year FREE Subscription to Fusion

Enter Today!

Contact a Kennametal Expert

Customer Support

Find customer support centers around the globe.

Item(s)

successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name: {{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Solid Carbide End Milling

- /

- DUO-LOCK Modular Milling

- /

- DUO-LOCK Modular End Mills • Corner Rounding and Chamfering Solid Carbide Tips

- /

- DUO-LOCK™ • KenCut™ CM • Multi-Flute • Metric

Product Similar To: [Product Name]

Sending to SolidCAM in progress...

Downloaded file will be available after import in the SolidCAM tool library.

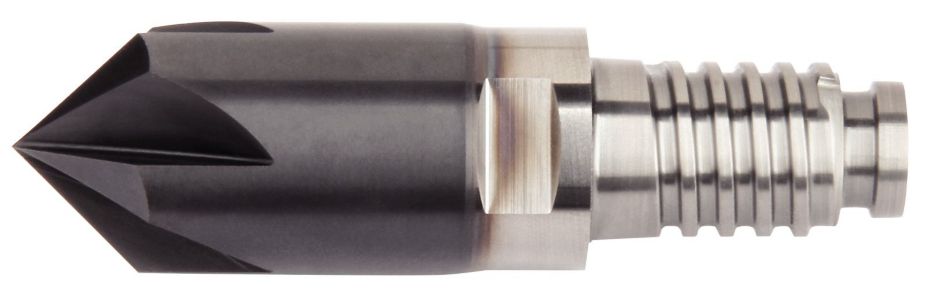

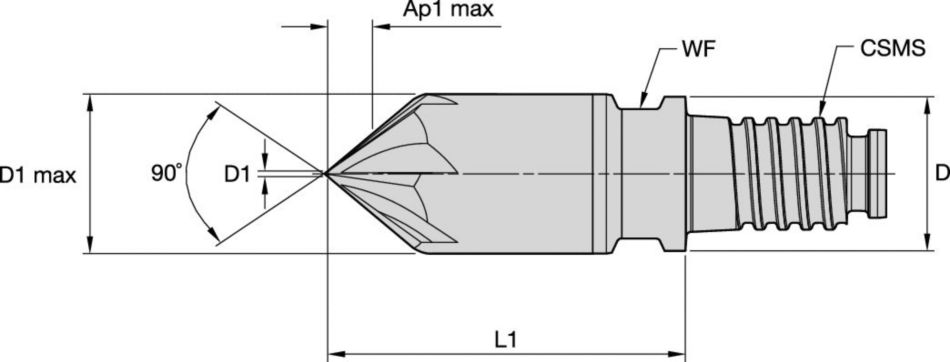

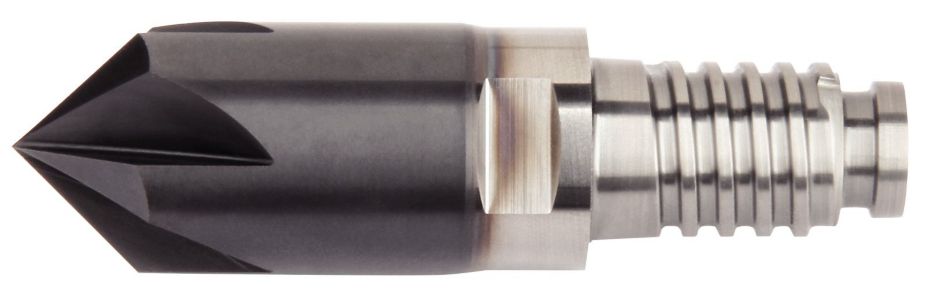

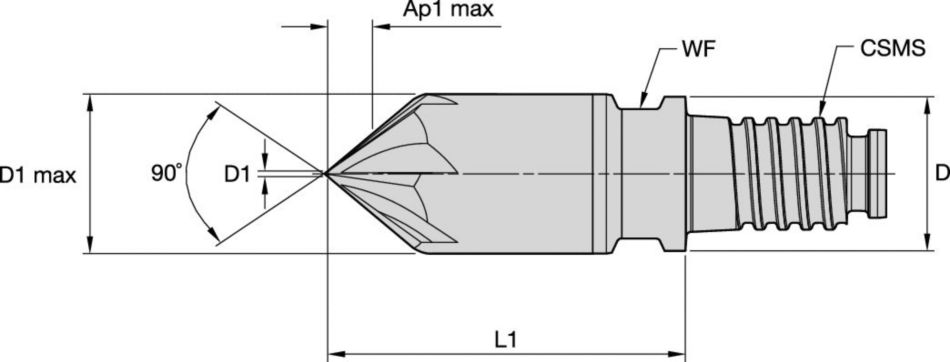

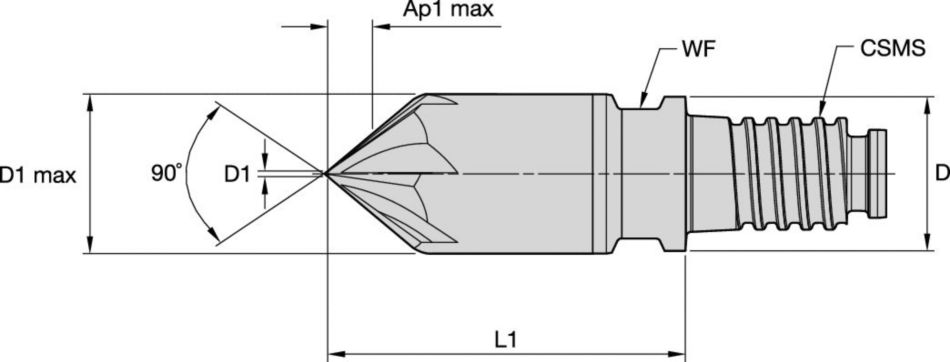

DUO-LOCK™ • KenCut™ CM • Multi-Flute • Metric

Modular End Milling • XADA Style

Features and benefits

- Modular end mill for chamfering applications in steels and stainless steels.

- Non-centre cutting.

Uses and application

Side Milling/Shoulder Milling: Eased Chamfer

Tool Dimensions: Flute Configuration: X (variable)

Helix Angle: 0°

| End Mill Tolerances | |

| D1 | tolerance h10 + / - |

|

|

0/-0,070 |

XADA • Metric

| Material

|

|

|

short | medium | long | Recommended feed per tooth (fz = mm/th) for side milling (A). | ||||||||||

| adapter reach | D1

|

|||||||||||||||

| KCPM15 | KCPM15 | KCPM15 | ||||||||||||||

| A | Cutting Speed

|

Cutting Speed

|

Cutting Speed

|

|||||||||||||

| ap | ae | Min | Max | Min | Max | Min | Max | mm | 10,0 | 12,0 | 16,0 | |||||

| P | 0 | 0,35 x D | 0,35 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,058 | 0,066 | 0,081 |

| 1 | 0,35 x D | 0,35 x D | 150 | – | 200 | 135 | – | 180 | 135 | – | 180 | fz | 0,058 | 0,066 | 0,081 | |

| 2 | 0,35 x D | 0,35 x D | 140 | – | 190 | 126 | – | 171 | 126 | – | 171 | fz | 0,058 | 0,066 | 0,081 | |

| 3 | 0,35 x D | 0,35 x D | 120 | – | 160 | 108 | – | 144 | 108 | – | 144 | fz | 0,048 | 0,056 | 0,070 | |

| 4 | 0,35 x D | 0,35 x D | 90 | – | 150 | 81 | – | 135 | 81 | – | 135 | fz | 0,043 | 0,050 | 0,061 | |

| 5 | 0,35 x D | 0,35 x D | 60 | – | 100 | 51 | – | 85 | 48 | – | 80 | fz | 0,039 | 0,045 | 0,056 | |

| 6 | 0,35 x D | 0,35 x D | 50 | – | 75 | 42,5 | – | 63,75 | 40 | – | 60 | fz | 0,032 | 0,037 | 0,046 | |

| M | 1 | 0,35 x D | 0,35 x D | 90 | – | 115 | 72 | – | 92 | 63 | – | 80,5 | fz | 0,048 | 0,056 | 0,070 |

| 2 | 0,35 x D | 0,35 x D | 60 | – | 80 | 48 | – | 64 | 42 | – | 56 | fz | 0,039 | 0,045 | 0,056 | |

| 3 | 0,35 x D | 0,35 x D | 60 | – | 70 | 48 | – | 56 | 42 | – | 49 | fz | 0,032 | 0,037 | 0,046 | |

| K | 1 | 0,35 x D | 0,35 x D | 120 | – | 150 | 108 | – | 135 | 108 | – | 135 | fz | 0,058 | 0,066 | 0,081 |

| 2 | 0,35 x D | 0,35 x D | 110 | – | 140 | 99 | – | 126 | 99 | – | 126 | fz | 0,048 | 0,056 | 0,070 | |

| 3 | 0,35 x D | 0,35 x D | 110 | – | 130 | 99 | – | 117 | 99 | – | 117 | fz | 0,039 | 0,045 | 0,056 | |

| N | 1 | 0,35 x D | 0,35 x D | 500 | – | 2000 | 400 | – | 1600 | 300 | – | 1200 | fz | 0,080 | 0,096 | 0,128 |

| 2 | 0,35 x D | 0,35 x D | 500 | – | 1500 | 400 | – | 1200 | 300 | – | 900 | fz | 0,072 | 0,086 | 0,115 | |

| 3 | 0,35 x D | 0,35 x D | 500 | – | 1500 | 400 | – | 1200 | 300 | – | 900 | fz | 0,056 | 0,067 | 0,090 | |

| 4 | 0,35 x D | 0,35 x D | 400 | – | 750 | 320 | – | 600 | 240 | – | 450 | fz | 0,056 | 0,067 | 0,090 | |

| 5 | 0,35 x D | 0,35 x D | 250 | – | 1000 | 200 | – | 800 | 150 | – | 600 | fz | 0,072 | 0,086 | 0,115 | |

| 6 | 0,35 x D | 0,35 x D | 100 | – | 750 | 80 | – | 600 | 60 | – | 450 | fz | 0,080 | 0,096 | 0,128 | |

| 7 | 0,35 x D | 0,35 x D | 100 | – | 750 | 80 | – | 600 | 60 | – | 450 | fz | 0,056 | 0,067 | 0,090 | |

| S | 1 | 0,35 x D | 0,35 x D | 50 | – | 90 | 40 | – | 72 | 30 | – | 54 | fz | 0,048 | 0,056 | 0,070 |

| 2 | 0,35 x D | 0,35 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,026 | 0,030 | 0,037 | |

| 3 | 0,35 x D | 0,35 x D | 25 | – | 40 | 20 | – | 32 | 15 | – | 24 | fz | 0,026 | 0,030 | 0,037 | |

| 4 | 0,35 x D | 0,35 x D | 50 | – | 60 | 40 | – | 48 | 30 | – | 36 | fz | 0,036 | 0,041 | 0,051 | |

| H | 1 | 0,35 x D | 0,35 x D | 80 | – | 140 | 64 | – | 112 | 48 | – | 84 | fz | 0,043 | 0,050 | 0,061 |