Product Similar To:

K284 (~3 x D) • K285 (~5 x D) • K715 • A-Shank • HP Drills

HP Drills • High-Temperature-Resistant Alloys • Through Coolant

Material Number1961387

ISO Catalog IDK284A02500ANSI Catalog IDK284A02500

Drilling

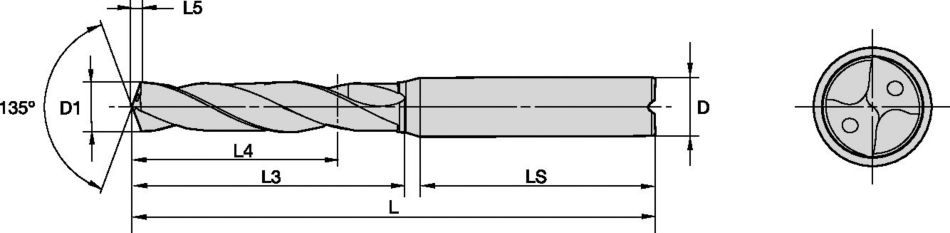

Tool Dimensions: 2flute/2margin/coolant

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1961387 |

| ISO Catalog ID | K284A02500 |

| ANSI Catalog ID | K284A02500 |

| Grade | K715 |

| [D1] Drill Diameter M | 6.35 mm |

| [D1] Drill Diameter M | .25 in |

| [D1] Wire Size | E |

| [L] Overall Length | 73 mm |

| [L] Overall Length | 2.874 in |

| [L3] Flute Length | 34.011 mm |

| [L3] Flute Length | 1.339 in |

| [L4] Maximum Drilling Depth | 25.9 mm |

| [L4] Maximum Drilling Depth | 1.019 in |

| [L5] Drill Point Length | 1.168 mm |

| [L5] Drill Point Length | .046 in |

| [LS] Shank Length | 36.5 mm |

| [LS] Shank Length | 1.437 in |

| [D] Adapter / Shank / Bore Diameter | 6.35 mm |

| [D] Adapter / Shank / Bore Diameter | .25 in |

Uses and application

Drilling

Tool Dimensions: 2flute/2margin/coolant

Drilling - Through Coolant

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Features and benefits

- HP Drills with Through Coolant for High-Temperature Alloys.

- Material-specific SC Drill for machining high-temperature-resistant alloys such as titanium alloys and nickel-based alloys in aerospace applications.

- Straight Cutting Edge for optimized chip formation with less stress and heat generation.

- Rigid wedge at the cutting corner to withstand high thermal and mechanical stress.

- K715™ Grade is a specified, uncoated 9% cobalt fine-grain carbide that helps to prevent built-up edge.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use