Product Similar To:

KCFM™ 45 • Carbide Insert • HDHN • Semi-Finishing

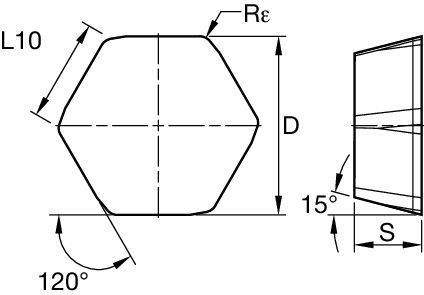

Milling insert with corner radii • Honed cutting edge

Material Number6969275

ISO Catalog IDHDHN070408ERANSI Catalog IDHDHN432ER

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6969275 |

| ISO Catalog ID | HDHN070408ER |

| ANSI Catalog ID | HDHN432ER |

| Grade | KCK20B |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | .5 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | .187 in |

| [L10] Insert Cutting Edge Length | 5.2 mm |

| [L10] Insert Cutting Edge Length | .205 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | .032 in |

| Cutting Edges per Insert | 6 |

Workpiece Materials

- Cast Iron

Features and benefits

Milling insert for cast iron and compacted graphite iron (CGI) machining.Indexabe milling insert with six cutting edges.Carbide inserts are ideal for machines with lower spindle capabilities.Low cutting forces.Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| – | İnce son işleme | Yarı Hassas İşleme | ||

| Malzeme grubu | Option 1: CBN | Option 2: Coated Carbide | Option 1: Advanced Material | Option 2: Coated Carbide |

| K1 | .S..R KBK50 | .E..R KC514M | .S..R KY3500/KBK50 | .E..R KC514M |

| K3 | – | .E..R KC514M | – | .E..R KC514M |

Feeds

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| -SR | 0,06 | 0,12 | -SR | |||||||||||||

| -ER | 0,10 | 0,18 | -ER | |||||||||||||

| İnce son işleme | Yarı Hassas İşleme | Kaba işleme |

Speeds

| Malzeme grubu | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 950 | 625 | 445 | 3935 | 2625 | 1970 | 3165 | 2870 | 2560 |

| 2 | 740 | 525 | 375 | 3935 | 2625 | 1970 | 2495 | 2245 | 2085 | |

| 3 | 625 | 445 | 360 | 3935 | 2625 | 1970 | 2100 | 1870 | 1705 | |

| Malzeme grubu | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 760 | 500 | 355 | – | – | – | – | – | – |

| 2 | 590 | 420 | 300 | – | – | – | – | – | – | |

| 3 | 500 | 355 | 290 | – | – | – | – | – | – | |

I have read and accepted the Terms & Conditions of use