Product Similar To:

RCMX

Inserts

Material Number1192416

ISO Catalog IDRCMX3209M076ANSI Catalog IDRCMX3209M076

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1192416 |

| ISO Catalog ID | RCMX3209M076 |

| ANSI Catalog ID | RCMX3209M076 |

| Grade | KC9125 |

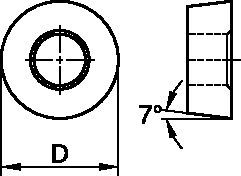

| [S] Insert Thickness | 9.525 mm |

| [S] Insert Thickness | .375 in |

| [D1] Insert Hole Size | 9.5 mm |

| [D1] Insert Hole Size | .374 in |

Features and benefits

Kennametal stocks a complete line of standard inserts for wheel and axle machining. Inserts are available in various styles, sizes, and grades.- Wheel boring — molded chipbreaker inserts in round, square, octagon, and regrindable inserts.

- Axle turning — triangle- and diamond-shaped inserts with chipbreakers.

- Wheel turning — rectangular and square styles, with or without molded chipbreakers.

- Wheel turning — round buttons with center hole for locking.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use